No matter how well we plan and manage our silage programs, some challenges arise that we cannot control. Weather, wildlife, and other factors can cause delays in covering our crop or air to be reintroduced to the silo during storage. For growers who are trying to overcome expected challenges that already make it difficult to achieve high-quality fermentation, these unexpected circumstances can cause quite the headache.

Luckily, there are ways that growers can arm themselves against these situations when ensiling forages, including using silage inoculants.

Air stress challenge

During storage, the goal is to keep the environment completely anaerobic so that the silage may remain stable until opening and feed out. Even with perfect management techniques, unforeseen circumstances can allow air into the silage mass. For example, when animals create holes in plastic covers or small leaks appear, it might be too late by the time they are even noticed.

When the silage environment becomes aerobic, many processes take place that will lead to an increase in pH, resulting in losses of DM and other valuable nutrients. Suppressing any increase in pH can combat these issues and keep silage more palatable and nutritious.

Putting silage inoculants to the test

Applying quality silage inoculants can help ensure a successful fermentation process, even when harvest conditions are less than ideal. In a recent study, alfalfa silages were subjected to varying lengths of air stress to imitate the out-of-control situations growers are commonly subjected to.

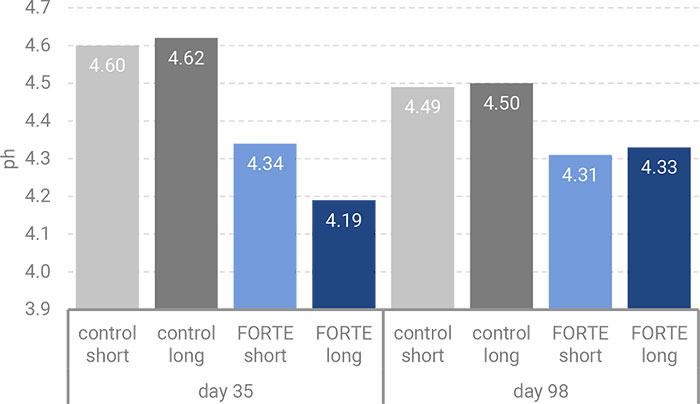

In the study, there were bouts of “short” (4 hours/week) and “long” (12 hours/week) air stress lengths applied to alfalfa silage to model situations where oxygen could be reintroduced during fermentation due to small leaks or holes created by animals or weather. Alfalfa silage included in this study was either untreated (control) or treated with an inoculant called BONSILAGE FORTE. This study shows that the treated silage could suppress the pH increase that came with air being reintroduced into a silage mass.

Figure 1: The pH of alfalfa ensiled for 35 and 98 days was recorded to determine BONSILAGE FORTE’s ability to control the pH increase of air stressed silage. Silage was either treated with no inoculant (control) or BONSILAGE FORTE (FORTE). During ensiling, the material was also either subjected to short air stress (short) at 4 hours per week or long air stress (long) at 12 hours per week. Source: Data from the University of Delaware, 2020

Natural buffering capacity

Alfalfa silages are known for their high buffering capacity due to high levels of protein and ash. That higher buffering capacity leads to alfalfa being one of the harder crops to ensile. The drop in pH in the front end of fermentation happens at a slower rate than in other crops, which also contributes to the challenge. There are many drawbacks to this slow drop in pH and one of those is that it takes longer to inhibit enzymatic protein degradation as well as harmful microorganisms like clostridia.

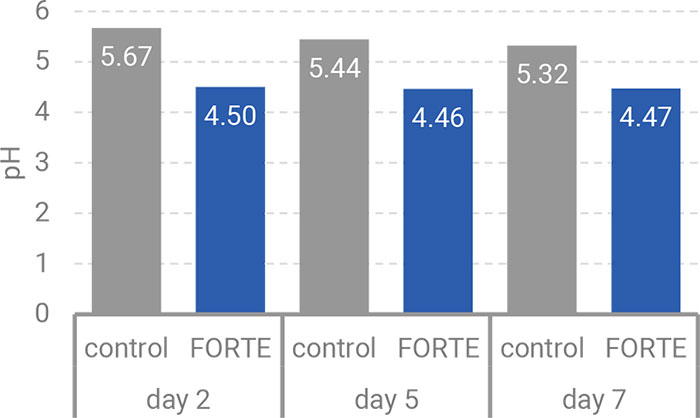

Applying the right silage inoculant can help growers overcome the slow pH drop rate. Research shows that using the BONSILAGE FORTE inoculant, growers can experience a more rapid drop in pH during the front end of fermentation.

Figure 2: Alfalfa silage was ensiled for 2, 5, and 7 days and the pH was measured to evaluate BONSILAGE FORTE’s ability to rapidly lower the pH in the front end of fermentation. Silage was either treated with no inoculant (control) or BONSILAGE FORTE (FORTE). Source: Data from the University of Delaware, 2020

With the ability to decrease pH at a more rapid rate in hard-to-ensile forages and combat the pH increase that comes with air penetration during ensiling, adding a silage inoculant into a crop plan can help growers protect their crop and provide cattle with high-quality forage.

To learn more about BONSILAGE FORTE and how it can help improve the quality of forage, visit BONSILAGEUSA.COM.