A well-established routine doesn’t always mean doing the same thing at the same time, every day. In fact, routines in a robotic barn are often anything but “routine.”

The size of the farm, the number of employees and layout of the barn are just a few of the factors that go into protocol development.

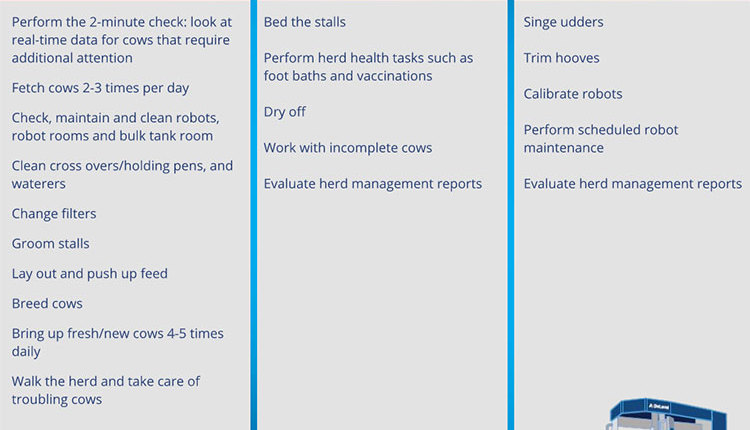

Routine tasks on small farms often provide more flexibility day-to-day, while large high producing herds will still adhere to more stringent routines and protocols to maintain a high production level. All robotic dairies start with the same, basic recommendations for daily and weekly tasks, and these are based on maintaining steady traffic to the robot in order to reach peak production.

Robotic Milking Routines

Bonus tip: Robotic dairies (of any size) that perform above average pay extra attention to a few parts of the recommended routines. Their robots are very carefully cleaned, they spend extra time training the fresh cows, and they act quickly on any alarm from the robot. Cows that need to be fetched are given extra attention, and data is carefully analyzed.

- VMS Usage and Robot Traffic. Pay attention to voluntary milking system (VMS) usage and evaluate what is happening around the farm when the robots are idle. Think about changing the routine to encourage a more consistent flow to the robots. However, when downtime does occur, you should use this time to schedule your washes, complete manually cleaning and perform maintenance.

- Herd checks, breeding and vaccinations. It is important to have protocols and schedules in place as to disturb the herd as little as possible. For example, instead of performing vet checks in the morning and completing the treatments in the afternoon, do both at the same time. This allows the cows more time to behave naturally.

- Barn design and the number of employees. Well-designed barns can accommodate more robots with fewer people, whereas a retrofit or a less than ideal layout will require a different level of employee skill and hours.

- Employee skill levels and strengths. Farms with less than eight robots need well-rounded employees. Farms with eight or more robots may choose to develop fewer, more specific skills per employee, such as breeding, feeding, or focusing on special needs cows. Farms with four or fewer robots require two full-time equivalents to take care of calving, calves, heifers and cows in an efficient barn layout.

- Herd management. Technology can help manage feeding, fresh cows, breeding, dry cows, calves and heifers by means of computer data, automated feeding systems, activity systems, body condition scoring systems, or cameras showing what is happening live in the barn on your phone. Employees who can manage cows, people and technology will be highly sought after.

With the right training for both the cows and employees, we can build a schedule that influences the herd’s routine for the convenience and management goals of the operator.