A healthy heifer calf is born. You milked the dam, tested her colostrum and fed the calf a high-quality meal all within an hour of birth. But, let’s get real. Delivering colostrum to newborn calves doesn’t always go that smoothly.

“As an industry, we’ve done a great job focusing on calving ease and getting calves on the ground in good shape,” says Dave Cook, Ph.D., technical calf consultant for Milk Products. “However, a management area we should focus our efforts to improve is day one calf care to help ensure calves achieve passive transfer.”

What are some common day one missteps? Where is there room for improvement? To find out the answers, let’s look at some real-life colostrum feeding scenarios:

Scenario 1 – Quality: You milked a fresh cow within an hour of calving. Her colostrum visually looks good, so you go ahead and feed it to the calf.

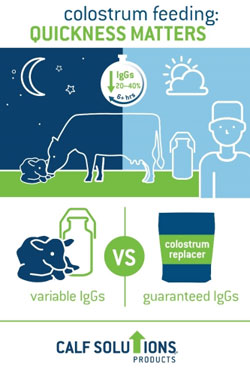

Too often we’re focused on getting colostrum in the calf as quickly as possible and we overlook testing colostrum quality. The true measure of colostrum quality is the concentration of immunoglobulins (IgG), which can only be determined by testing.

“Colostrum quality varies significantly from cow to cow and farm to farm,” says Cook. “Studies have shown IgGs can vary from 14.5 to 132.7 grams of IgG per liter of colostrum. Without testing, some calves will receive colostrum outside of the acceptable range.”

To measure colostrum quality and ensure calves are getting colostrum with acceptable levels of IgG, use a Brix refractometer or colostrum tester. Target a Brix reading of at least 22 and a colostrum tester reading of at least 50. These readings indicate the colostrum contains 50 grams of IgG per liter.

If you don’t have enough quality colostrum for newborn calves, feed a colostrum replacer with guaranteed levels of IgG. Look for a bovine-derived colostrum replacer with 150 grams of IgG per feeding.

Resolution: In this scenario, the colostrum should have been tested before feeding it to the calf. If it tested outside of the acceptable range, a colostrum replacer should have been fed to guarantee adequate levels of IgG are delivered to the calf.

Scenario 2 – Quickness: A cow calved just after midnight. It’s 5 a.m. now but you won’t be able to milk her and feed colostrum until 6 a.m., at the earliest.

There’s a lot to accomplish on a dairy farm every day. Getting fresh cows milked shortly after calving isn’t always easy. However, maternal colostrum IgG concentration is highest at calving and decreases with every passing hour due to resorption of proteins and dilution from milk letdown.

“Cows milked six hours or more after calving have significantly lower IgG concentration,” says Cook. “A fresh cow’s IgG concentration can easily decrease by 20 to 40 percent, leaving the calf shortchanged.”

The gold standard is to collect colostrum within four hours of calving and feed it to the calf within 30 minutes of collection. With every passing hour, a calf’s ability to absorb IgGs decreases. This standard puts a timer on colostrum protocols.

If you can’t harvest colostrum within four hours of calving (or harvested colostrum isn’t high enough quality), a colostrum replacer can be fed quickly – open the bag, mix and feed.

Resolution: In this scenario, at least six hours will have passed by the time the cow is milked and her colostrum’s IgGs will have decreased. A colostrum replacer should have been fed to guarantee adequate levels of IgG are delivered and absorbed by the calf sooner.

Scenario 3 – Cleanliness: You milked a fresh cow within an hour of calving. But before you have a chance to feed the colostrum to the calf, you get tied up with something else and the colostrum has sat out for two hours.

If colostrum sits at room temperature for any length of time, bacteria in the colostrum will grow quickly. If colostrum with a high bacterial load is fed to the newborn calf, you risk introducing the calf to disease and interfering with IgG absorption.

Consider feeding a colostrum replacer when the risk of bacterial contamination in maternal colostrum is high. High bacteria are likely when colostrum is dirty, bloody or the fresh cow is sick.

“The feeding process for a colostrum replacer includes fewer steps where contamination can occur,” says Cook. “It also provides biosecurity benefits by reducing the risk of colostrum-transmitted diseases such as Johne’s, bovine leukosis virus (BLV), mycoplasma and salmonella.”

Resolution: In this scenario, feeding the colostrum that sat out for two hours poses a disease risk to the calf and interferes with IgG absorption. A colostrum replacer should have been fed to eliminate the disease risk and ensure optimal IgG absorption.

Real-life scenarios like these don’t have to stand in the way of your calves achieving passive transfer. Keep a quality, bovine-derived colostrum replacer on hand to help get calves off to a healthy start.

Find a colostrum replacer that meets your calf program needs at CalfSolutions.com.

Milk Products, based in Chilton, Wis., manufacturers high-quality animal milk replacers and young animal health products. Using its innovative manufacturing technology, Milk Products produces over 700 unique animal nutrition products for numerous independent feed manufacturers, wholesale distributors, and large retail chains. Our customers choose whether these products are sold under their private label brand, or under the Sav-A-Caf® brand which is manufactured and marketed by Milk Products.