My success is attributed to my forages," said Jerry Dakin, a fifth-generation Florida dairyman. "There's nothing better than feeding fresh forages," he explained. The Myakka City operation green chops four loads of grasses in the morning and another four loads in the afternoon.

"It costs me about $11 per ton to grow and harvest it," said the entrepreneurial dairyman.

A dose of urea adds nitrogen to keep the grasses growing.

Dakin green chops about 650 acres of forages each year with roughly 20 acres harvested each day creating a 30-day rotation.

"We want to harvest our bermudagrass, triticale, and ryegrass on a regular cycle to maximize forage quality," he said. Jiggs burmudagrass is the preferred hybrid, and it stays in production for four years. That's followed by a rotation of triticale, silage corn, and then back to bermudagrass.

Of course, the green chop fits perfectly in Dakin's business model because the Florida growing season covers 11 of the 12 months each year.

"December is my lowest forage month. The month is wet and miserable. That's when I feed bagged grasses and step up the corn silage's contribution to the ration," said Dakin. Throughout the remainder of the year, Dakin adds 4 pounds of corn silage to the total mixed ration's forage dry matter. That number more than doubles in December.

Dakin Farms feeds three rations to the milking herd: a fresh cow, high and low milk cow. Dakin works with nutritionist Rick Lunquist to feed a mineral premix. Everything else is mixed in-house to save money, with yeast also being added to the ration.

While the growing conditions may seem ideal to those located throughout the northern U.S., Dakin quickly confides, "Crops need to be babied' in the hot, humid Florida climate."

Keep it chilled

It was just five years ago when Jerry and his wife, Karen, started the processing plant.

"It has been a real eye-opener," said Jerry. "We gained a lot of knowledge, and especially learned a great deal about interacting with consumers and meeting their needs. Every dairy producer should have a better understanding of our customers even if he or she doesn't directly sell their milk."

On the plant's first day, the Dakins processed a mere 600 gallons of milk. Momentum has built tremendously since then. Today, 90 percent of Dakin's milk is being processed from the farm's 2,260 mostly Holstein herd with the main product being bottled milk. However, the Dakin's fresh cream product, a new venture, now goes into over 1,000 restaurants.

The cream venture proves that Jerry and Karen are customer focused and routinely meet with people to learn how they can better serve needs.

"At first, our fresh cream didn't sell well. So we started talking to chefs," Jerry recalled. "We told them our cream has a better flavor profile because it's fresh . . . only pasteurized at 165°F, while ultra-high pasteurized (UHT) cream is heated to 212°F. That higher temperature can give cream a burnt flavor," he said.

After meeting with chefs, cream sales took off.

"Orders were so strong this Christmas season we had to tell customers that we could only fill 70 percent of placed orders. Talk about grumpy chefs when they could not get their cream!" he exclaimed.

These days the dairy plant represents a growing business capable of storing and processing up to 20 tanker loads of milk on-site at any one time.

The newest venture involves starting up a cheese-processing center. Allen Bassler Jr., who relocated from Virginia, is heading up that project. If the name Bassler sounds familiar, it should, as he is the breeder of six-time World Dairy Expo Brown Swiss Grand Champion Snickerdoodle.

Bassler is just one example of the many positive, people-orientated employees the gregarious Dakin couple have attracted to their joint farm and processing venture.

In meeting with bankers to start the latest business entity, Dakin had projections, but he also had faith.

"I am like Noah, I am going to build the processing plant," Jerry told bankers as he referenced the Noah's Ark story of Biblical fame. "God's been with us on this project," said Jerry, noting he and Karen pray on a regular basis. Each week the couple also shuts the entire business down for an employee lunch. At that time, the Dakins and their managers recognize employee birthdays and anniversaries. Additionally, ministers who speak Spanish and English conclude with a short prayer service for interested staff.

For the business, the biggest challenge these days is producing enough milk in summer.

"Once I built my new freestall barns, I knew I had to breed better cows," said Jerry, who dabbled with crossbreeding along with some other breeds in recent years. "We've got to keep our processing plant full, and we will do that by using the best Holstein genetics available moving forward," he said, explaining he wants to step up cow cooling. too.

Balancing finances is important to Jerry and Karen to grow both parts of the business.

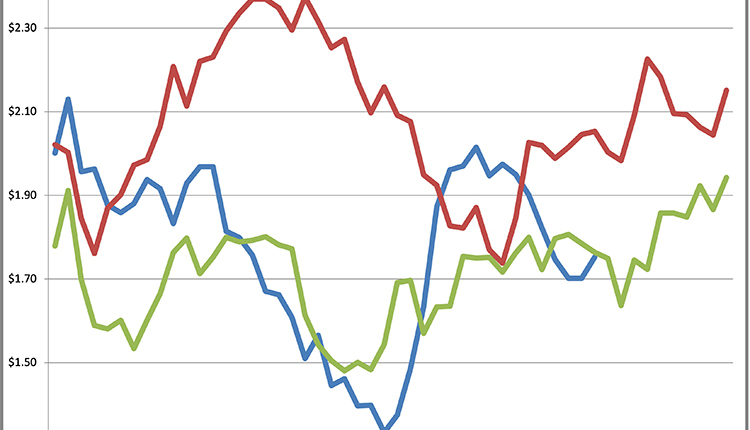

"In 2014, the processing plant paid about a $1 less per hundredweight (cwt.) to the farm for its milk to keep the plant cash flowing," he said. "However, we are making that up now as the plant pays $2.15 per cwt. above prevailing market prices to the farm."

Dakin added that both businesses are thriving. When combined, the debt per cow for the farm and dairy plant is $1,300 per cow. That figure is well below industry average for a dairy farm all by itself.

>Full of life

The Dakins have added a number of additional enterprises to their family business portfolio.

"If you don't have passion, don't do it," said Dakin.

As part of the processing plant, Jerry and Karen also established an education and retail center.

That is Karen's passion. Last year alone, some 15,000 school children and adults came through the facility from October through June.

"We all have to play our part educating consumers about agriculture," said Karen.

A few years back, Dakin purchased a 260-acre dirt mine out of bankruptcy for 10 cents on the dollar. He now employees six full-time excavators and a host of dump truck drivers who haul soil to a number of projects.

"Orders are so strong, a dump truck leaves our mine once every 57 seconds," he said.

Taking advantage of backhauls on those same trucks, Dakin accepts stone, concrete, and trees at that site. The stone and concrete get ground and resold. As for the tree and biomass, those products either get resold to a cellulosic ethanol plant or burned in the recently installed incinerator on-site. The resulting ash gets applied as fertilizer on nearby farm fields.

As for the future, the Dakins want to give back to others.

Presently, the dynamic duo have been researching the establishment of a faith-based drug rehabilitation center. If realized, that dream would not only help heal people with his or her addictions but provide job training at the various Dakin enterprises.

"God has blessed us," said Jerry. "We want to share those blessings with others."