A rapid decline in pH is crucial to achieving an optimal silage fermentation, preserving silage nutrients, and maximizing the feed’s value. Research-proven bacterial inoculants are valuable tools in driving this rapid pH decline amidst the many variables that can affect the ensiling process.

‘Bad bugs’ damage forage quality

Clostridia and enterobacteria have detrimental effects on silage quality. They are epiphytic microorganisms, meaning they are found everywhere. These microorganisms consume quality proteins and produce ammonia, butyric acid, and biogenic amines (such as putrescine and cadaverine), causing a decline in nutritional quality and palatability, and creating silage that may be dangerous to feed to cows. At low dry matter (DM) and high pH, both clostridia and enterobacteria can outcompete lactic acid bacteria, resulting in massive spoilage. When fed to livestock, clostridial silages result in lower DM intake and reduced animal performance.

Recently, Dr. Limin Kung Jr., a global leader in silage research, was asked, “What is the most important part of making quality silages?” He discussed creating the right environment at harvest to quickly drive down the silage pH. A more acidic environment (lower pH) in the silo, resulting from rapid lactic acid production, limits the growth of undesirable microorganisms, such as clostridia and enterobacteria, and the damage they cause.

Therefore, proper ensiling techniques — including the proper DM at harvest, adequate packing, and prompt sealing — are crucial in minimizing the growth of these detrimental bacteria and preserving silage quality. Bacterial inoculants can also play a key role in lactic acid production and the subsequent rapid pH decline.

Inoculating, sealing, and preserving silages

The most important part of sealing a silo is doing it safely. Employee exhaustion, weather, and loss of daylight can increase the danger associated with covering a pile. Silages should be covered as soon as they can be by alert employees who are able to see clearly and work safely. Many producers describe bacterial inoculants as “an insurance policy” for situations of delayed sealing and other silage management challenges.

A recent trial ensiled 26.5% DM triticale to simulate a difficult-to-ensile crop. Silages were untreated or inoculated with Vita Plus Crop-N-Rich® MTD/1®, stored in 2-gallon bucket silos, sealed either immediately or after 24 hours, opened after 124 days of ensiling, and analyzed.

Results from this trial highlighted:

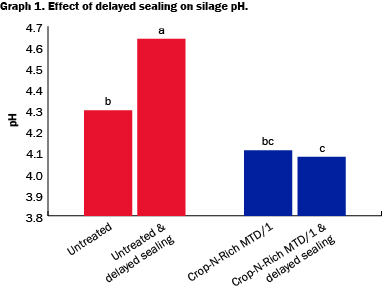

- Even though the silos were packed to a good density, delaying sealing of silages resulted in a higher pH (Graph 1) and less lactic acid.

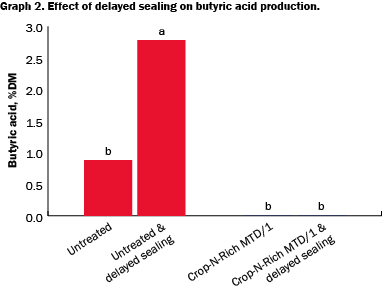

- Silages that had a higher pH — either due to a lack of inoculation or delayed sealing — had higher levels of butyric acid.

- Inoculating the silages with a high-quality inoculant, such as Crop-N-Rich MTD/1, decreased the pH and was a successful treatment to prevent the growth of clostridia and production of butyric acid (Graph 2).

- Inoculating the silages with Crop-N-Rich MTD/1 overcame the challenge of delayed sealing, underscoring the value of inoculants as an insurance policy should there be management challenges.