While at the sixth annual AgSTAR conference last week, Jerry Bingold had plenty to announce. First, he explained all the initiatives that the Innovation Center for U.S. Dairy was taking part in, and they were plentiful. Beyond their own initiative to map the carbon footprint of the U.S. dairy industry (the only industry to take a full-fledged look at the statistic: http://bit.ly/Hoards_GHGReduction) other companies and industries are now working with the dairy industry to find opportunities to work together to symbiotically benefit from renewable energy.

The major announcement was that the Innovation Center will work as part of a new national research program to work with the Idaho Center for Advanced Energy Studies focused on the economic viability of dairy farms and rural communities. The agreement states that its objectives are to:

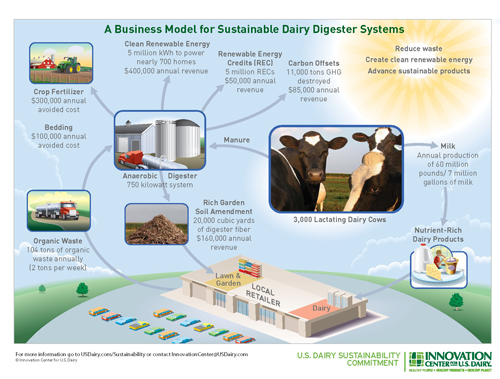

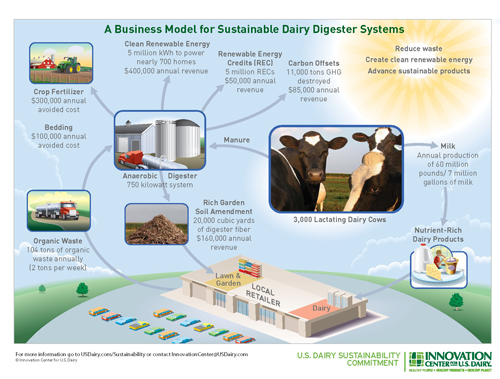

But this week, the Innovation Center revealed a true cost-benefit analysis for anerobic digesters (you may remember from last week http://bit.ly/Hoards_Pipe_Dream that digesters were the main topic of the conference). The below picture gives us a great idea of all the inputs and outputs used on a 3,000-cow dairy with a digester. Further, the Innovation Center used real data from an Idaho dairy to show the potential profit of one of these devices on a similar-sized farm.

While scaling down the technology to the under-500-cow-size farm is taking some time, showing proof of a 3,000-cow digester is a step in the right direction. At the AgSTAR conference last week, the stated goal was to have 1,300 anaerobic digesters operating on farms across the country by 2020. While many presenters mentioned the lofty goal (that's one every other week), most agreed to keep moving towards it.

We're at about 165 on-farm digesters today (and growing), but the landfill industry in the U.S. has over 300 biogas collection units as of 2008 (though their "digester" is inexpensive, as the landfill itself is the digester).

To see a cost breakdown, click here.

Click on image below to see an enlarged pdf

The major announcement was that the Innovation Center will work as part of a new national research program to work with the Idaho Center for Advanced Energy Studies focused on the economic viability of dairy farms and rural communities. The agreement states that its objectives are to:

- Collect baseline data on nutrient and manure management practices to assist in the identification of best practices for dairy farms

- Identify opportunities for dairy farms of all sizes to increase renewable energy production through anaerobic digesters, gasification, and composting

- Research best management practices for farm-based renewable energy production on small, medium, and large farms

- Analyze the U.S. utility grid infrastructure, electric rates, and renewable energy incentives applicable to dairy farm operations

- Identify opportunities to increase funding of national research on sustainable dairy practices, manure management, substrates, renewable energy technologies, and smart grid applications

- Facilitate technology-based economic development

But this week, the Innovation Center revealed a true cost-benefit analysis for anerobic digesters (you may remember from last week http://bit.ly/Hoards_Pipe_Dream that digesters were the main topic of the conference). The below picture gives us a great idea of all the inputs and outputs used on a 3,000-cow dairy with a digester. Further, the Innovation Center used real data from an Idaho dairy to show the potential profit of one of these devices on a similar-sized farm.

While scaling down the technology to the under-500-cow-size farm is taking some time, showing proof of a 3,000-cow digester is a step in the right direction. At the AgSTAR conference last week, the stated goal was to have 1,300 anaerobic digesters operating on farms across the country by 2020. While many presenters mentioned the lofty goal (that's one every other week), most agreed to keep moving towards it.

We're at about 165 on-farm digesters today (and growing), but the landfill industry in the U.S. has over 300 biogas collection units as of 2008 (though their "digester" is inexpensive, as the landfill itself is the digester).