Updates from Hillcrest Farms include changes in our milk production process. If we are not making plans or changing protocols, are we striving to do better? Dad has always asked me about my five-year plan and 10-year plan. Then there’s a follow up question about my next five-minute plan because there is more work to be done.

We transitioned to robotic milking in 2019. We visited a lot of voluntary milking system (VMS) barns and decided a free-flow setup would probably be a good fit for us. This is where cows can move freely in whatever direction they would like, get milked whenever, and eat and drink at any time. It’s completely up to them unless they get a certain number of hours past their last milking and end up on our “fetch cow” list. We typically walk each side of the barn to bring cows to the fetch pen three times within 24 hours. This list will normally contain freshly calved cows and cows that are a long time since last being milked.

We knew a free-flow style robotic barn would cause us to have more fetch cows than a guided-flow barn. We weren’t exactly sure how many more, but we knew that the number would be elevated. I’ve talked with many farmers who run guided-flow barns that have only a handful of fetch cows. At any given time here, we have 50 on average in the total barn, so fetching for a guided-flow barn might take 15 to 20 minutes whereas here, it can take up to 2 hours to finish up an entire fetch group. You don’t want more than about seven cows standing in the fetch pen at a time because you wouldn’t want a cow standing waiting for more than an hour.

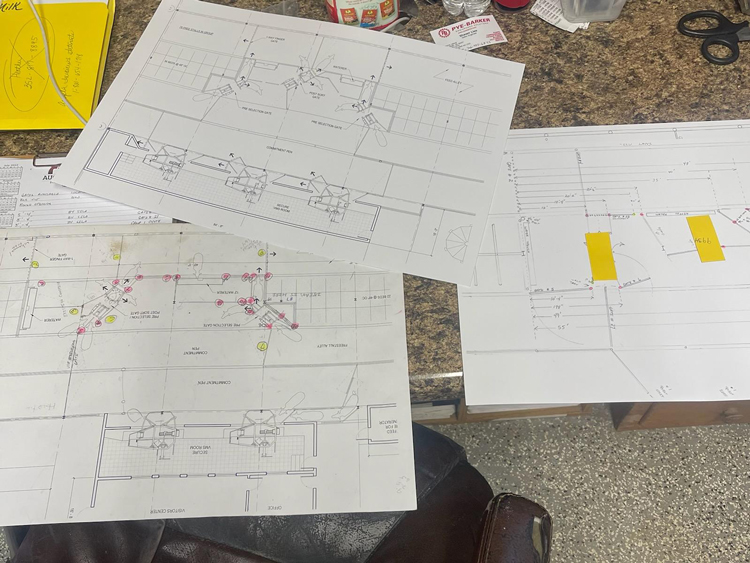

We are continuously trying to be more efficient anywhere we can. At this point on our farm, we have realized the fetching needs the most focus. So, over the past year we have been blueprinting and trying to figure out what’s the best way to do a better job. We have decided to change from a free-flow to a modified guided-flow system.

We will put in finger gates and smart gates that the cows will continuously go through while walking around the barn. The smart gates will help direct them to the robots when it is time for them to milk. We hope that this will help bring down those fetch cow numbers. This will free up labor to do other things that we are not getting done because we don’t have enough time.

We start construction soon, and then it will be another training period for the girls. We are excited to move forward with this project!

Mark and Caitlin Rodgers are dairy farmers in Dearing, Georgia. The Rodgers have a 400-cow dairy that averages 32,000 pounds of milk. Follow their family farm on Facebook at Hillcrest Farms Inc.