Like most of you, our feeding strategy has been to trim costs while keeping the cows milking well, healthy, and breeding back on time. What to cut and by how much has been the big question for everyone over the past few years.

Our basic ration ingredients have changed little in recent years. We use custom operators and put our own hay silage and corn silage in 12-foot bags. At present, we're feeding corn silage and hay silage at a 1.3 to 1.0 ratio on an as-fed basis.

We've considered using a bunker or silage pile as our herd has grown. However, we haven't been willing to make the investment in either a concrete or asphalt area and the run-off containment that such a switch would involve. Our bags are on a gravel pad.

Tackled shrink

One approach we've taken to reduce feed costs has been to cut field-to-bunk waste or shrinkage of our forage. By improving drainage in the silo pad area, reorienting our bags, trying to stay on top of rodent and bird damage, and being more meticulous at feedout, we have cut silage shrink loss by as much as half. We now figure we are in the 12 to 15 percent range and are working toward the industry goal of 10 percent or less.

We're pricing hay silage into our ration at $53 a ton and corn silage at $27. Every 100 pounds of hay silage "saved" puts $2.65 on the bottom line.

We also tried to trim feed costs by reducing refusals. Our main two milking groups now are running 1.7 and 1.3 percent weighbacks.

Keeping components

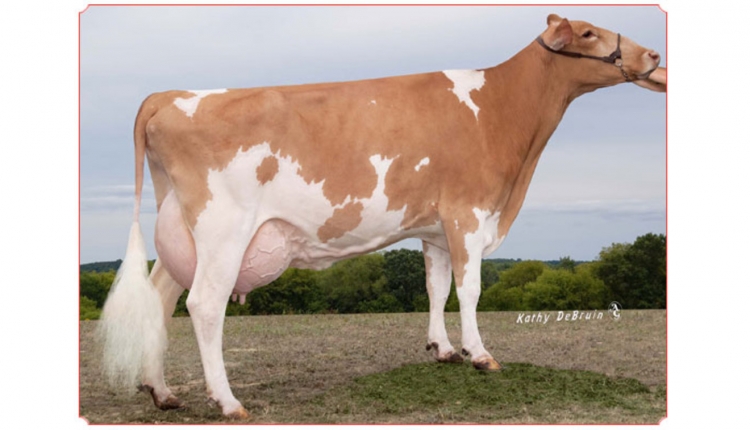

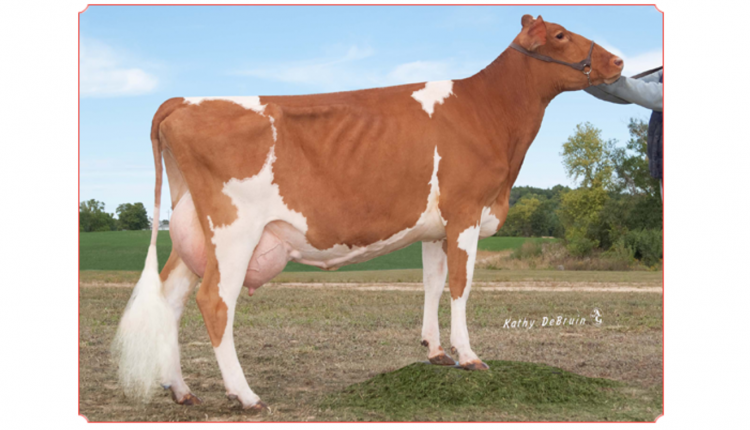

We use amino-acid balancing to help milk protein levels and have cut total protein levels slightly to 16.5 protein (17.5 for our high-group). This past April, our milk averaged 4.93 percent fat and 3.57 percent protein, and one-third of our milking cows were Jerseys. On last test day, the Guernseys were producing 3.19 pounds of fat per day and 2.18 pounds protein. The Jerseys were producing 3.2 pounds of fat per day and 2.27 pounds of protein.

We calculate pounds of fat and protein shipped per stall per day as a measure of the dairy's productivity and efficiency. We are producing about 5.4 pounds of combined fat and protein per stall per day.

When things got tight about two years ago, we stopped feeding a protected-amino acid product. While on-farm trials are tough to interpret, we believed our protein levels drifted downward enough to justify putting the product back in the ration.

Last January and February, we worked with our feed supplier, Vita Plus, and Elanco on an ionophore (Rumensin) trial. We had been putting 11 grams per ton in our protein supplement which meant our cows were getting about 256 milligrams each per day. During the eight-week trial, we raised the level fed per cow per day by 50 milligrams every two weeks. We worked up to 470 milligrams per cow.

We saw no deleterious effects on milk components and milk stayed steady. Throughout the trial, our tank average stayed at or above 5 percent fat.

A liquid whey product is going into our milking group rations at about 10 pounds or 1 gallon per day. Each 3,000-gallon tank has two common sump pumps . . . one to keep the delactosed whey in suspension and the other to pump it into the mixer. We did not heat the whey last winter and did not have freezing problems.

Wet brew and whey

To spare corn usage, we are feeding about 15 pounds of wet brewers grains and about 10 pounds of a delactosed whey product per cow per day to our milking groups. We store the wet brew outdoors within walls formed by big concrete blocks. There have been some inconsistencies in supply. In fact, we have batch recipes formulated for "full" wet brew, "half" wet brew, and no wet brewers grains.

The whey product has been a relatively convenient, dependable, and low-cost source of energy. We store it in two 3,000-gallon poly tanks, each equipped with two common sump pumps. One pump runs off and on to keep the whey in suspension, and the other pumps the whey into the feed mixer. We did not heat the product in the winter and did not have freezing problems.

The product we're using is 27.5 percent total solids and 54 percent lactose (dry basis). It is 2.65 percent sodium and 5.27 percent chloride, also on a dry matter basis. We've learned you need to send samples to a milk lab to get an accurate analysis.

Improving transition-cow care and fresh-cow starts has been an ongoing goal. We believe the greatest gains we've made have been due to giving close-ups a more comfortable environment with plenty of resting and manger space. (See page 403 in this issue.)

Of course, close-up rations are important, too. Intakes for our variable group of Guernseys and Jerseys averaging about 12 days before calving is in the range of 21 to 22 pounds. They get 33 pounds of corn silage and 9 pounds of low-potassium grass hay. Sometimes, chopped straw replaces the grass hay. But the last time we switched from chopped straw to chopped grass hay we saw about a 4-pound boost in intakes. The supplement contains canola meal and soybean meal.

High fiber/low energy

Nonfiber carbohydrate level is 32 percent with net energy-lactation at 0.61 mcal/pound. ADF-fiber is 30.7 percent, and NDF-fiber is 47.3. Starch is 18 percent, and sugar is 3.2.

Getting consistent intakes has been a challenge. We have brought in a tube grinder to reduce particle size of the grass and straw. Still, we saw some sorting so we tried a feeding strategy that seems "all wrong" at first glance.

We went to every-other-day feeding. That way, there was always feed in front of the cow, and it stayed relatively consistent. One area herd with a 36,000-pound rolling average actually feeds close-ups every third day during cold weather. We will go back to once-a-day feeding of the close-ups during warmer weather.

We have seen marked reductions in fresh-cow problems . . . providing we give close-ups at least 100 square feet of actual bedded-pack resting space.

1106_412