By Amanda Smith, Associate Editor

Row upon row of plastic silage bags frame the driveway at the Hoard's Dairyman Farm. Yet, plastic is a double-edged sword.

In its many forms, from bunker silo covers to bale wrap, plastic has earned its reputation as a superior cover for fermented feedstuffs. But the plastic itself presents significant disposal challenges.

To gain a greater understanding of the volume, frequency and current disposal methods of agricultural plastic in Wisconsin, the University of Wisconsin-River Falls and the Department of Natural Resources, in conjunction with Organic Valley and Crave Brothers Farmstead Cheese Company, conducted a survey of organic and nonorganic dairymen within the state.

In addition to these two producer groups, surveys were mailed to all licensed nurseries, greenhouses and marinas. In total, 1,540 usable responses were received.

Three-fourths of respondents generated waste ag plastic or boat wrap last year. Eighty-four percent of nonorganic dairymen and 92 percent of organic operators noted that they generated waste plastic.

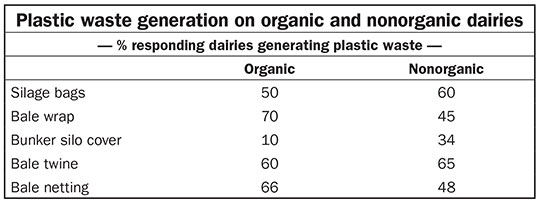

The frequency of generation varied by plastic type and industry. Bale twine, bunker silo covers, bale wrap, bale netting and silage bag waste generation exceeded all other plastic waste products.

Overall, landfilling was found to be the most frequent disposal method, followed by burning for the five common dairy industry-related plastics listed above.

At the present time, a third of respondents currently have no disposal cost for their waste plastic. An additional 23 percent pay less than $100 per year. Meanwhile, 25 percent pay at least $500 per year for plastic removal.

The vast majority (85 percent) of respondents would be willing to transport their waste plastic to a collection site for free disposal. Approximately 32 percent of those surveyed are willing to travel 10 miles or less for free disposal.

Within the state of Wisconsin, and likely in many other strong dairy areas, a steady supply of waste agricultural plastic is generated. There is also interest among generators to recycle the waste plastic they produce. The researchers note that, based on the data collected, the next step is studying the feasibility of developing systems and facilities to recycle waste agricultural plastic.