When choosing a milk replacer, calf raisers often look at two key ingredients: fat and protein. But did you know there are four major ingredients in milk replacer?

"Milk replacers are made with four major components: protein, fat, lactose and ash. All four work in collaboration with one another,” says Skip Olson, Technical Services Veterinarian for Milk Products, LLC, Chilton, Wis.

Protein and fat are traditionally used to describe a specific milk replacer’s formulation, with the first number representing protein and the second, fat. For example, a 24:20 milk replacer would contain 24 percent protein and 20 percent fat.

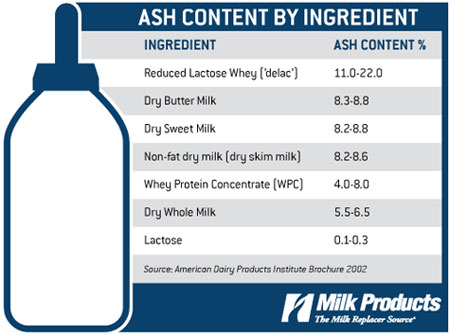

Ash (mineral) percentage is determined by the ash content of the various ingredients.

“Ash is a naturally occurring substance in milk- and plant-based feed products,” says Olson. “It is made up of minerals, including sodium, potassium, chloride, calcium and trace minerals. Many of these essential elements contribute to the cellular function of calves that allow for both growth and strong immunity.”

The fourth ingredient, lactose, is variable. Its percentage changes because it completes the formulation based on the protein, fat and ash content. In a 20:20 milk replacer with 10 percent ash, lactose would make up the remaining 50 percent. If the protein level was changed to 24 percent, lactose would drop to 46 percent.

“Whole, raw milk contains about 5.5 to 6.5 percent ash,” says Olson. “Milk replacers usually contain more ash because they often are manufactured using primarily milk-based ingredients that concentrate natural minerals.”

An example is reduced-lactose whey, or “delac,” which is a coproduct of cheese production.

Milk replacers also often contain additional additives – trace minerals, vitamins and medications – which increase ash content. The result is a 7 to 12 percent range in commercial milk replacers, with most containing about 9 percent ash. Olson says a higher number is not necessarily detrimental to the calf for a number of reasons:

- Protein, fat and lactose are variable influencers. Protein is required by the calf for lean tissue and structural growth. Fat and lactose combine to provide energy to fill in the skeletal frame. Ash levels only become “too high” and limit growth when they don’t allow for enough lactose to provide a total energy package that maximizes growth based on the amount of protein in the ration. Even in those cases, the setback in weight gain is minor. For example, when a 25:20 milk replacer containing 9 percent ash is fed at 1.5 pounds of dry matter per day, National Research Council (NRC) predicted gain at 60 degrees Fahrenheit is reduced by only 0.03 pound per day compared to a formulation containing 7 percent ash. Over a 5-week period, that amounts to just a 1-pound difference in total gain.

- Feeding rate matters. Using the same formulation of 25:20 milk replacer but increasing the feeding rate to 2 pounds of dry matter per day means the 9 percent ash level won’t have any influence on predicted gain. That’s because feeding at this higher rate provides more than enough available energy (fat + lactose) to accommodate the protein in the ration.

- Cost of adjustment usually is not recouped in gain. The primary challenge in manufacturing milk replacers is providing high-quality nutrition at the least cost. “Delac” often is a key ingredient to accomplish both. It is higher in ash than other common ingredients. But, given the examples above, it can be used to develop milk replacer formulations that still result in acceptable ash levels. For example, choosing a 12 percent ash product versus a 9 percent product saves $1.50 to $2.00 per bag, while sacrificing only 2 pounds of total predicted gain for the first 5 weeks of feeding.

- Moisture also is a factor. Probably a more important variable than ash is moisture level in milk replacer. Moisture can vary from 2.5 to 7 percent. As an example, a bag of milk replacer with 7 percent moisture has 4 percent less dry matter (and 4 percent more water) than a bag with 3 percent moisture. That represents a 50-pound bag of milk replacer with 2 pounds less dry matter and nutritional value. Essentially, you’re paying for added water. High moisture content has a much more detrimental effect on calf growth and cost efficiency than high ash content. A 20:20 milk replacer with 7 percent moisture, fed at the same volume as a 20:20 formulation with 3 percent moisture, will result in 0.07-pound lower average daily gain, or a total of 2.45 pounds of gain in the first 5 weeks of feeding.

Olson says the last example is especially telling, because the two bags of milk replacer likely would sell at a very similar price.

“Unlike ash, where a small sacrifice in gain would be offset by a more affordable product, moisture levels at the high end of the acceptable range usually do not come at a lower price. But they have similar, or more profound, impact on gain,” he states.

“Ash is not added to milk replacer as a ‘filler,’” says Olson. “It is a natural and varying component based on the ingredients selected for the formulation.”

Milk Products milk replacers are available through distributors. To locate a dealer near you, call 920-849-2348 or email mpinfo@milkproductsinc.com. For more information about other calf nutrition products, visit calfsolutions.com.

Milk Products, based in Chilton, Wis., manufacturers high-quality animal milk replacers and young animal health products. Using its innovative manufacturing technology, Milk Products produces over 700 unique animal nutrition products for numerous independent feed manufacturers, wholesale distributors, and large retail chains. Our customers choose whether these products are sold under their private label brand, or under the Calf Solutions® and Sav-A-Caf® brands, which are manufactured and marketed by Milk Products.