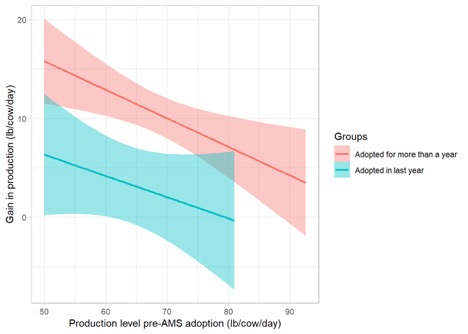

Overall, robotic milking systems tend to boost milk production. Those reported gains depend on the production level before automatic milking systems (AMS) adoption, as shown in the figure. Survey results support the conventional wisdom that AMS leads to higher milk production, in part because of enhanced milking frequency.

We also noticed a steep learning curve for AMS management . . . most producers indicated that they needed about six to 12 months to operate AMS at a satisfactory level. This also shows up in the figure as an average 6- to 8-pound difference in reported production gains between those with less than a year of AMS experience (greenish blue) and those with over a year of experience (red).

More at play

The reported production gains shown in the figure cannot be solely attributed to AMS. Changes in other aspects of operation such as housing, bedding, and feeding are all factors that tend to be associated with production gains.

Unfortunately, we also observed cases of stagnant or reduced production after the adoption of AMS. Various reasons may explain this. Besides the normal learning curve associated with AMS management, some have clearly experienced additional difficulties in adapting to the technology and in finding the right support.

To aid producer learning and the exchange of information surrounding AMS management, we have launched a virtual peer group, ComMoonity–Robotic Milking. We welcome current and prospective robot users to join and participate in its Q&A format interactions.

Keep in mind that gains in milk production do not guarantee financial gains. Other factors will affect the profitability of AMS including future milk prices, capital cost, and labor savings. To help producers evaluate these factors we also maintain the AMS planning tool, which we will update in the coming months using the information collected through the survey.

About the survey

Data for this analysis comes from a survey jointly conducted by dairy extension educators at the University of Wisconsin, University of Minnesota, and Penn State University. We thank those who provided their inputs to our survey, and we continue to invite others who are also operating AMS. Click here for the online survey.

To comment, email your remarks to intel@hoards.com.