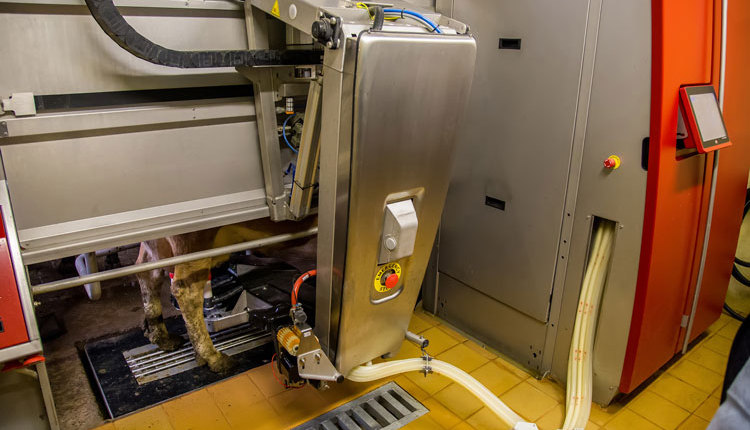

Milking robots offer a number of advantages. An automatic milking system (AMS) tends to boost production, reduce labor, and provide valuable data to help with day-to-day herd management.

These attributes offered by robots come with a large up-front investment. Then there is the ongoing maintenance and repairs. However, those maintenance and repair costs vary widely on farms. That’s illustrated by our current survey of dairy farmers, jointly conducted by dairy extension educators at the University of Wisconsin, University of Minnesota, and Penn State University.

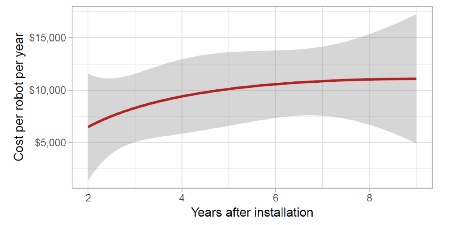

We asked producers to report their average maintenance and repair costs over the last three years or since AMS units were installed on each specific dairy. In the early years, repairs and maintenance total around $5,000 per robot per year on average. Those average costs climbed to around $10,000 as the AMS unit got older. This is mainly due to higher repair costs, since maintenance costs remained somewhat constant over the AMS’s lifespan.

We gleaned this cost-related insight based on more than 50 complete answers from dairy farmers. The estimated average repair and maintenance costs, as a function of the age of the AMS units, are shown in the figure.

It must be kept in mind that repair and maintenance cost estimates varied considerably. Among our respondents who had installed AMS units five years ago or more, 25 percent reported maintenance and repair costs above $15,000 per robot per year. That includes a few producers who reported costs above $25,000 per robot per year. In their comments, those respondents made it clear that adaptation to AMS didn’t go well for them and that they were transitioning back to conventional milking systems or exiting the dairy sector.

Service is critical

A key element believed to help minimize the risk of failed AMS adoption is the availability and quality of customer service from AMS dealers. Our survey shows that a majority of producers are satisfied with the customer service they received. Perhaps more importantly, 45 percent have indicated improvements in customer service since they first adopted AMS.

Join the community

To aid producer learning and the exchange of information surrounding AMS management, we have launched a virtual peer group, ComMoonity–Robotic Milking. We welcome current and prospective robot users to join and participate in its Q&A-format interactions. And to help producers evaluate the financial implications of AMS adoption, we also maintain the AMS planning tool, which we will update in the coming months using the information collected through the survey.

We thank those who provided their inputs to our survey, and we continue to invite others who are also operating automatic milking systems to participate. The online survey is available at z.umn.edu/DairyRobotSurvey.