On many dairies, the milking equipment is the hardest working but often the most neglected equipment. Even most old farm trucks get the oil changed on a regular basis, but for some reason we think that the milking equipment will just keep working without any regular maintenance.

Think about it. Dairy producers are relying upon this equipment to harvest the milk, which is the largest source of income on a dairy farm, yet little attention is given to the maintenance and monitoring of the milking equipment. At Quality Milk Production Services (QMPS), we perform many system evaluations over the course of a year, and at a recent internal training we asked the question: “What are the most common milking equipment-related issues that we see?” We thought it would be helpful to the dairy industry to share what we came up with in hopes that you can implement some of the suggestions for preventing these issues rather than having them happen on your farm as well.

Top equipment concern

Failure of one or more pulsators is often identified during our regular herd surveys and milking center audits. The surprising part is that many of these are routine evaluations that are not necessarily associated with current issues on the farm.

If you watch a cow being milked with a bad pulsator, you will notice how painful it is for the cow. Many times these cows kick the unit off before they are finished milking. This leads to more problems with manure contamination of units and cows leaving the milking center half full of milk.

Training your milkers to recognize what pulsators are supposed to be doing and how to tell if they are not working can go a long ways in detecting this problem quicker. Monitoring the milking equipment reports on a daily basis can also help.

Most important, though, is regular graphing and rebuilding of your pulsators by your milking equipment dealer. This will help keep them running well and minimize the number of pulsators that fail between visits. If they are detecting bad pulsators at every visit, then they should graph them more often and try to identify the most common reason that they are failing.

For some farms, we have seen success with filters in the pulsation lines. Other farms have switched the style of short pulsation tubes if there is an issue with them constantly coming off and drawing in dirt and manure. These little changes can make a big difference to keeping the heartbeat of your milking system working well.

One way to determine if a pulsator has failed is to turn each milking unit on at the start of milking, insert your fingers into the teat cups, and feel the liner opening and closing. If the liner stays completely open or completely closed, then the milking staff should immediately notify management of the issue. It is also possible to feel the pulsing air in the short air tubes by lightly squeezing them, but turning the milking unit on and inserting your fingers into the teat cups is a more definitive way to identify pulsation failure.

Vacuum levels that are not where the farm wants them is another common failure on our regular herd visits. On many farms, there is not a working vacuum gauge or no one is checking it on a daily basis, and so the inappropriate vacuum level may have existed for some time.

On a recent system check, we found a system vacuum at 20.3 inches of mercury (inHg)! You can imagine that the cows were not chewing their cud during milking on this dairy.

There are numerous issues we find that lead to this, such as nonfunctional vacuum sensors for the variable frequency drive (VFD), water in the sensing tube of the VFD, nonfunctional regulators, and inaccurate gauges being used to set the vacuum level. Most times, these problems can be corrected very quickly once they are detected, but the issue is preventing problems from happening and noticing quickly if they do occur. On many farms where this has happened, they have implemented a system to record the vacuum levels at the farm gauge on a daily basis so that the problem is detected much quicker.

Another common issue that we see on farms is milk line vacuum levels that do not stay within the National Mastitis Council (NMC) guidelines of no more than 0.6 inHg above or below the average. This is either picked up on our milk line vacuum during milking or else on the unit fall-off test during a full NMC evaluation.

For many of these herds, we are also running claw vacuum levels and can see the variation in the claw vacuum levels as shown below in the circled areas on Figure 1 that proves that the cow is also experiencing large fluctuations. There again are numerous issues that we see leading to this such as a poorly functioning regulator, too much air leakage in the system, inadequate pump capacity, slugging in the milk line, poor positioning of a VFD sensor, and an inappropriately tuned VFD. Having your equipment dealer perform an annual NMC evaluation as well as routine preventative maintenance of your regulator and pump can go a long ways to detecting this or preventing it from occurring.

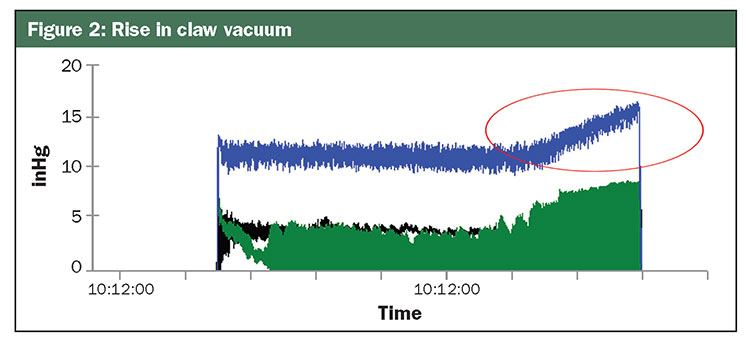

On newer installations, we have seen an issue with the vacuum creeping too high when only a small number of units are left on cows. Figure 2 is an example of the claw vacuum on one poor cow that happened to be the last one on. Notice how the blue line (claw vacuum level) goes dramatically up at the end of milking to almost 17 inHg.

This cow was very unhappy by the time the unit came off. This issue is related to large pumps not being allowed to run slow or stop, and so the vacuum level continues to climb when there is not enough air being admitted to the system.

The fix for this is very easy by simply installing an “air leak” in the system, but again the issue is one of noticing that this is occurring. Installing a clean air filter over the area where the “air leak” or “weep holes” have been introduced into the system is advised in order to maintain clean air being introduced in the vacuum system.

After repeatedly finding this type of situation, we now routinely document the vacuum level on our system checks with no units on. If you think this might be an issue, have your equipment dealer check your system’s vacuum levels with no milking units attached.

Nimble creatures

Cows are remarkable animals and sometimes it amazes us what they will adjust to over time, but there is a breaking point. Pulsation failure and inappropriate vacuum levels can dramatically increase the risk of mastitis on your dairy if it goes undetected.

Hopefully, the examples above have sparked your thoughts about how you can more effectively monitor and prevent these equipment failures on your dairies. Good luck — your cows will thank you.