It has become very common for farms to store forages such as corn silage and haylage in concrete bunker silos or drive-over piles. To help facilitate proper fermentation and prevent spoilage, it is extremely important to pack these feeds densely and consistently as they are brought into the storage structure.

Packing can be accomplished with tractors, usually carrying extra weight. A forage packer is a tool that can be attached to a tractor as it drives over the feed pile. The weight of the packer is concentrated through its wheels to effectively remove trapped air. This condenses the feed, encouraging fermentation and reducing spoilage. Another benefit is feed can be stored in a smaller area.

Agromatic in Fond du Lac, Wis., makes BigFOOT silage packers in several sizes. Hoard’s Dairyman staff had the opportunity to visit their facility to learn how a 9-roller forage packer is manufactured.

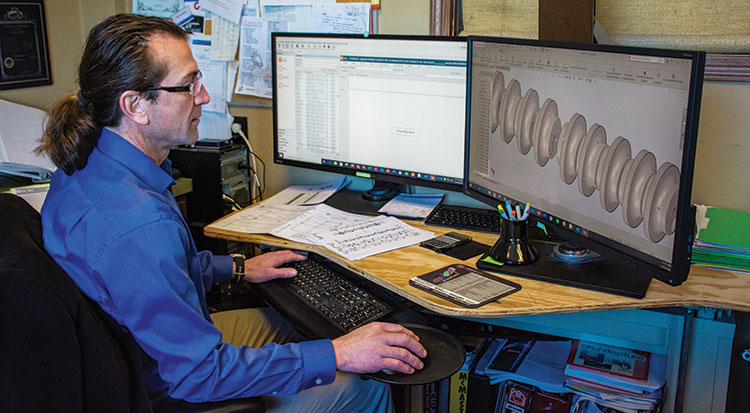

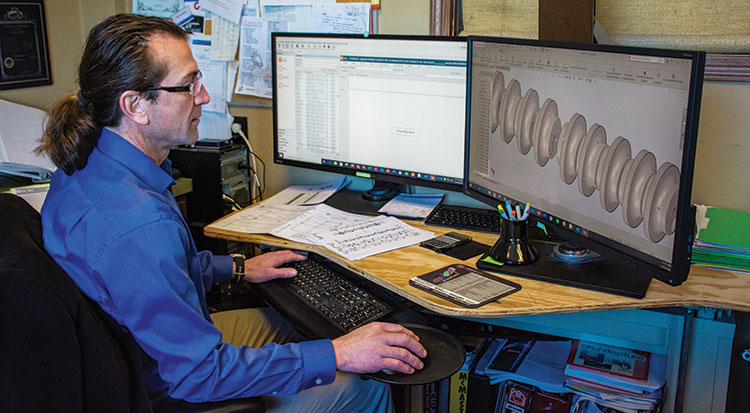

1. The drawings that will be used to build the packer are created with a computer program. There are certain features that can be configured on each packer, including the number of rollers, the hitch category size, and the type of lubrication system.

2. The rollers or wheels are what roll over the feed. Each wheel consists of two halves, which are made of mild steel and are spun offsite. The two halves are attached to a hub and then wrapped with a stainless steel band that is welded into place. The wheels are shipped offsite to be filled with concrete to add weight.

3. The axle for the packer is made of a cold rolled, high strength steel shaft. It is cut to the right length, and three holes are drilled into each end.

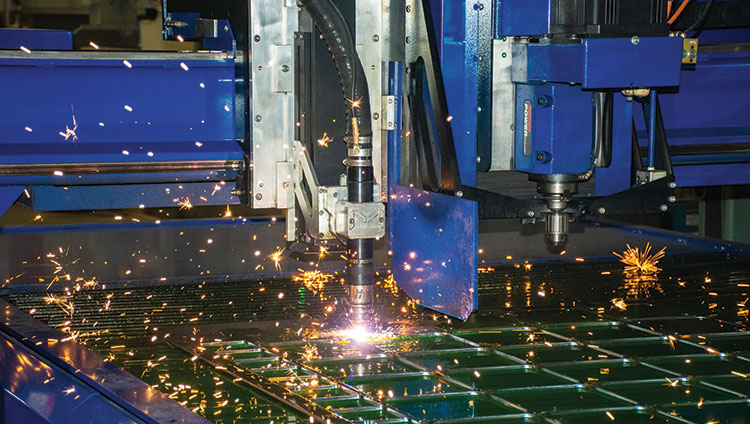

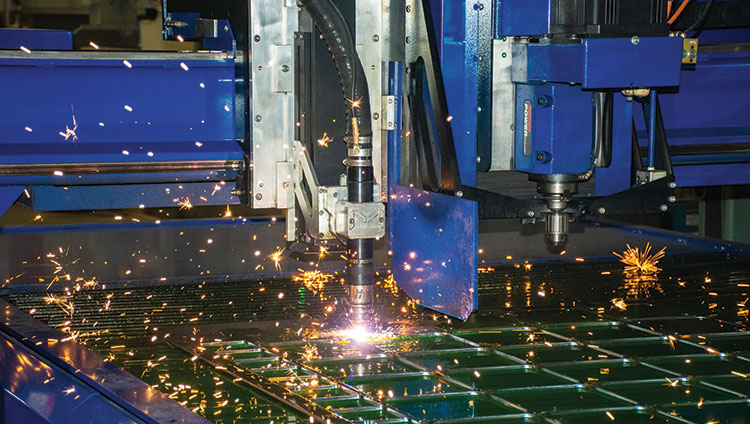

4. Components of the frame, hitch, and legs are cut with a high-definition plasma laser. These components are made from heavy carbon steel.

5. Next, the components are welded together. Once complete, these weldments are cleaned, powder paint coated, and then baked, which provides greater durability and rust protection.

6. While the frame powder-coated painting is outsourced, other pieces of the packer are painted in house.

7. The finished wheels are placed in an assembly jig, which allows these heavy pieces to be moved easily from one stage of assembly to the next. Bushings are set on locating brackets between each wheel. Next, the axle shaft is inserted through the wheels and brushings, and then heavy-duty, split-type bearings are fitted.

8. After the axle caps are attached, the frame is lifted onto this subassembly and mounted. The lubrication system is installed and primed. Legs are inserted into each end of the frame. Product and safety decals are applied. The owner’s manual housing and serial number plate is mounted.

9. Custom-made concrete blocks are fabricated in two sizes. They fit into the packer’s frame and are secured on the farm using chains. These blocks provide additional weight for packing.

10. Once the hitch pins are installed, final quality checks are made. The packer is now complete and ready for the harvest season.