A corn harvester performance study conducted from 2018 to 2019 looked at four hybrids planted at farms to see if the type of hybrid impacted kernel processing. The hybrids had differences in plant size, relative maturity, and kernel type.

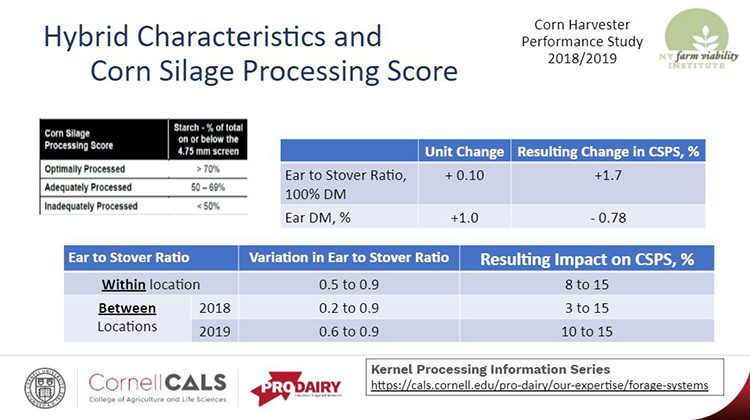

“Based on our data . . . for each 0.1 unit change in ear to stover ratio, it resulted in 1.7-unit gain in kernel processing score,” said Joe Lawrence of PRO-DAIRY at Cornell University.

“On the ear dry matter, for every one unit increase in ear dry matter, those kernels got harder and harder and more difficult to process, and so we lost about .34 of a point in processing score for every one unit increase in ear dry matter,” he said during ‘Improving Harvest Management’, during the 2021 Virtual Forage Congress hosted by Cornell Cooperative Extension.

He continued, “This is just reminding us . . . as we go from one field to the next, and maybe we’ve planted different hybrid types on the farm . . . we really need to be paying attention to kernel processing score.”

Consider digestibility and availability

When kernel processing, farmers also need to consider digestibility and availability.

The guidelines for KPS are:

> 70% - optimum

50% to 70% - adequate

< 50% - inadequate

Lawrence pointed out that it is common to collect fecal samples and see how much of the kernel is passing through the animal.

“What it comes down to less of digestibility factor . . . kernel processing is about availability, and ultimately doesn’t matter how digestible starch is if it’s still encapsuled in the kernel and passes right through the animal as a whole kernel,” he said. “It doesn’t matter if it’s 60% digestibility or 85% digestibility at that point, because it’s not available.”

Kernel processing helps break down the kernel to improve the availability of that starch, but there are more questions to answer when it comes to costs.

Too much processing

“Is there such a thing as overprocessing?” he asked. “Is there a point of diminishing returns in terms of return on investment? If above 70 is optimum, is there really a benefit of getting to a score of 80, and how much money would we want to invest in equipment to get that score?”

Lawrence noted that farmers have seen kernel processing scores can improve during fermentation, but in their study they did not see a significant change between the kernel processing score at harvest and after fermentation.

“Just a reminder . . . keep an eye on whole plant dry matter and test whole samples, versus a windshield checks or plant color, or milk line check of the ears. We have to kind of combine it all together,” he said.