The information below has been supplied by dairy marketers and other industry organizations. It has not been edited, verified or endorsed by Hoard’s Dairyman.

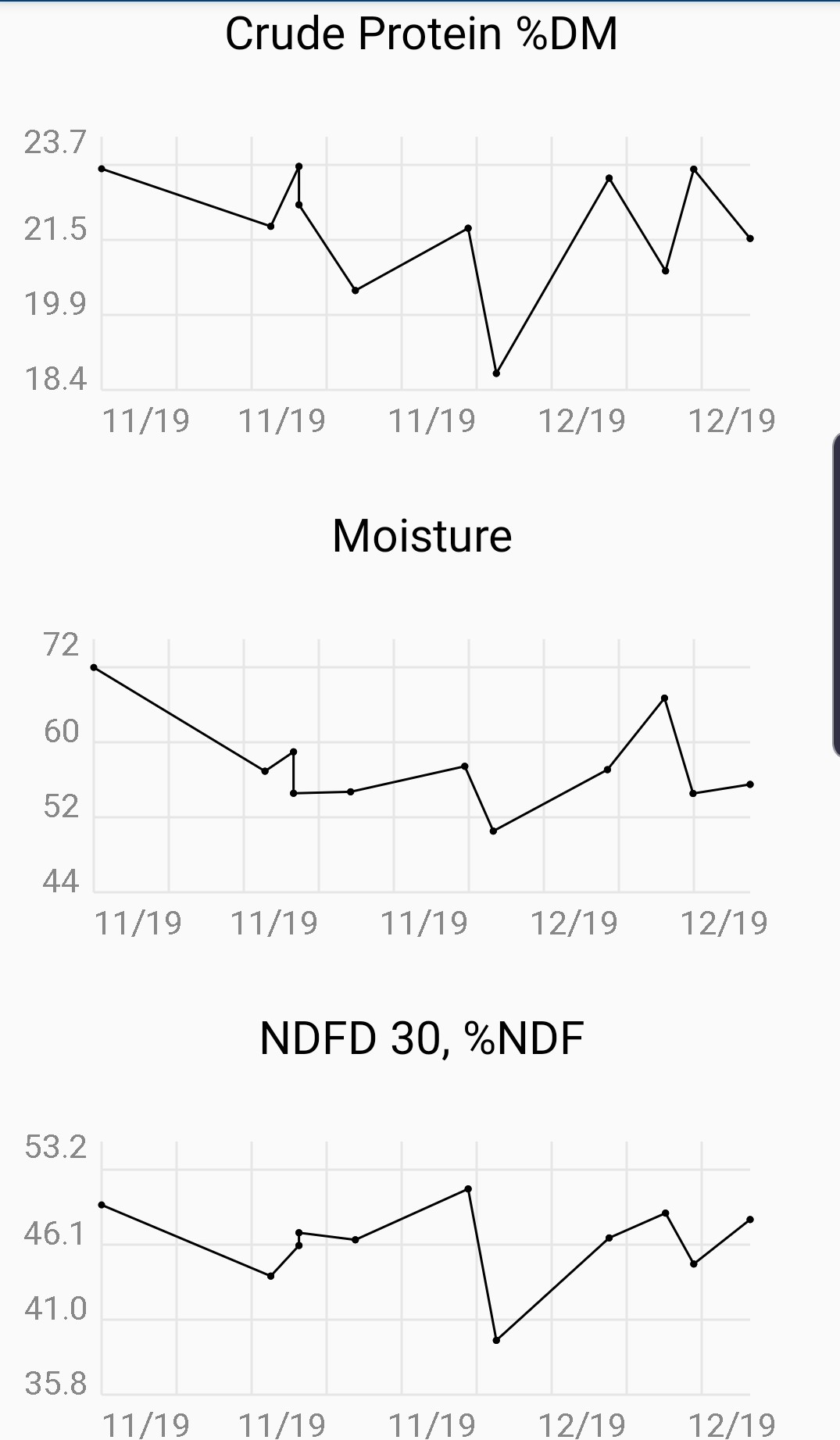

Innumerable trials and research have been conducted to look at this feedstuff variation and how to reduce it. Figure 1 showcases variation of laboratory results over time from multiple haylage samples pulled from the same farm – begging the question: which number is most accurate?

Figure 1: Haylage variation over time

“While there is potential for some lab variation, most of this variation of results between samples occurs prior to being sent to the lab,” explains Cliff Ocker, Rock River Laboratory Director of Sales and Client Relations. Understanding this, it’s important to look at the variation that can be caused by improper sampling and review better processes to reduce it.

Capture a representative sample

The first step is ensuring that the lab receives a representative sample.

“Keep in mind all of the variation in the forage that is brought in off of the field, from the low-lying areas to the hilltop, ranges in maturity, potentially different soil types, diseases, and weed or pest control,” says Ocker. “How can we encompass all of that in one sample that gets sent to the lab?”

For example, when only three bales from a stack are sampled, Relative Feed Value (RFV) can vary by over 70 points!* “By pulling material from different locations [or more bales], the variation decreases significantly,” states Ocker.

This does add an additional step - meaning that more sample of the feedstuff needs to be initially pulled than what is needed for the lab. Starting with a larger sample obtained from the source, mixing and subsampling to get an appropriate amount for the lab, will help prepare a more representative sample.

“While typically less than a pound of material is sent to the lab, the lab can only analyze what is sent to them,” explains Ocker. “Doing all you can to make sure the lab gets a representative sample will help reduce variation.”

Tracking harvest

Another way to help predict variation at feedout is to track any known variation as the forage is harvested.

“For those using silos, as elements change during harvest – such as cutting, field, or hybrid- throw some egg cartons or newspaper into the blower. This way, at feedout you know when the feedstuff is changing and a new sample may be required,” suggests Ocker. “If bags are used for storage, have spray paint or a marker handy to mark on the side of the bag to track where a change will occur.”

Sample sizing

When sampling feeds coming in from the fields, Ocker recommends grabbing material from multiple loads and keeping them in a clean bucket, and refrigerated, until ready to prepare a sample for the lab. The entire contents should then be dumped onto a clean surface, mixed well, and divided into four equal parts.

“Slide two quarters of this material away and mix the remaining two, divide again into four equal parts, and remove two again and continue until you have a small enough amount,” directs Ocker. “Enough material to fill a quart size bag is needed to send to the lab for analysis.”

He also cautions, “When sampling from a larger face such as a bunker, PLEASE remember SAFETY FIRST, do not go near the face of a bunker that is higher than you can reach". Rather, have the farm feeder either deface or scoop material from the face and either place it into a clean mixer to mix before sampling, or put it on a clean surface (away from the bunk face) to grab material for the same splitting procedure.

“More material should be gathered than needed but from multiple spots, then mix and split into the four quadrants until you are down to an appropriate sample size,” continues Ocker.

Several videos demonstrating proper sampling procedures are available on YouTube to help perfect the process.

Accurate sampling begets accurate analysis

The performance of production animals, whose feed and forage are being sampled, is dependent on the accuracy of the results that are received back.

“I’ve heard stories from nutritionists that, on a cold day, may just drive the truck close enough to the bunker face to reach out and grab a sample to shove in a bag to send to the lab, then balance a complete diet based on those results,” says Ocker. “With today’s economics, we are seeing greater value put on watching and monitoring feedstuff variation, as monitoring the variation provides an opportunity for increased profitability.”

Averaging multiple samples from the same source can help significantly, but being sure to provide the most representative sample to the lab is an even better starting point.

Founded in 1976, Rock River Laboratory is a family-owned laboratory network that provides production assistance to the agricultural industry through the use of advanced diagnostic systems, progressive techniques, and research-supported analyses. Employing a team of top specialists in their respective fields, Rock River Laboratory provides accurate, cost-effective, and timely analytical results to customers worldwide, while featuring unsurpassed customer service.