The information below has been supplied by dairy marketers and other industry organizations. It has not been edited, verified or endorsed by Hoard’s Dairyman.

“Snaplage brings starch like high moisture shelled corn, but also a bit of fiber like corn silage,” explains John Goeser, animal nutrition, research, and innovation director for Rock River Laboratory. “Snaplage often blurs the lines between grain and silage, and its quality is dramatically affected by harvest timing.”

In this year of expensive corn, producers have additional incentives to optimize snaplage quality and dairy or beef performance. Moisture, kernel maturity, and kernel processing are key aspects of snaplage quality that are generally under the producers' control through harvest timing and managing the processor roll game.

“Kernel processing score is a useful tool to assess kernel breakage with corn silage and snaplage, with today’s goal being 75 to 80 percent kernel processing score,” shares Goeser.

For insight into managing harvest timing and snaplage moisture, a better understanding of how moisture relates to both starch content and starch digestibility can help.

“Starch content increases with advancing corn crop maturity and decreasing kernel moisture content,” explains Goeser. “However, gains in starch must be balanced against decreasing rumen starch digestibility as the grain matures and fermentation potential is lessened with drier feed.” This delicate balance holds true for both corn silage and snaplage.

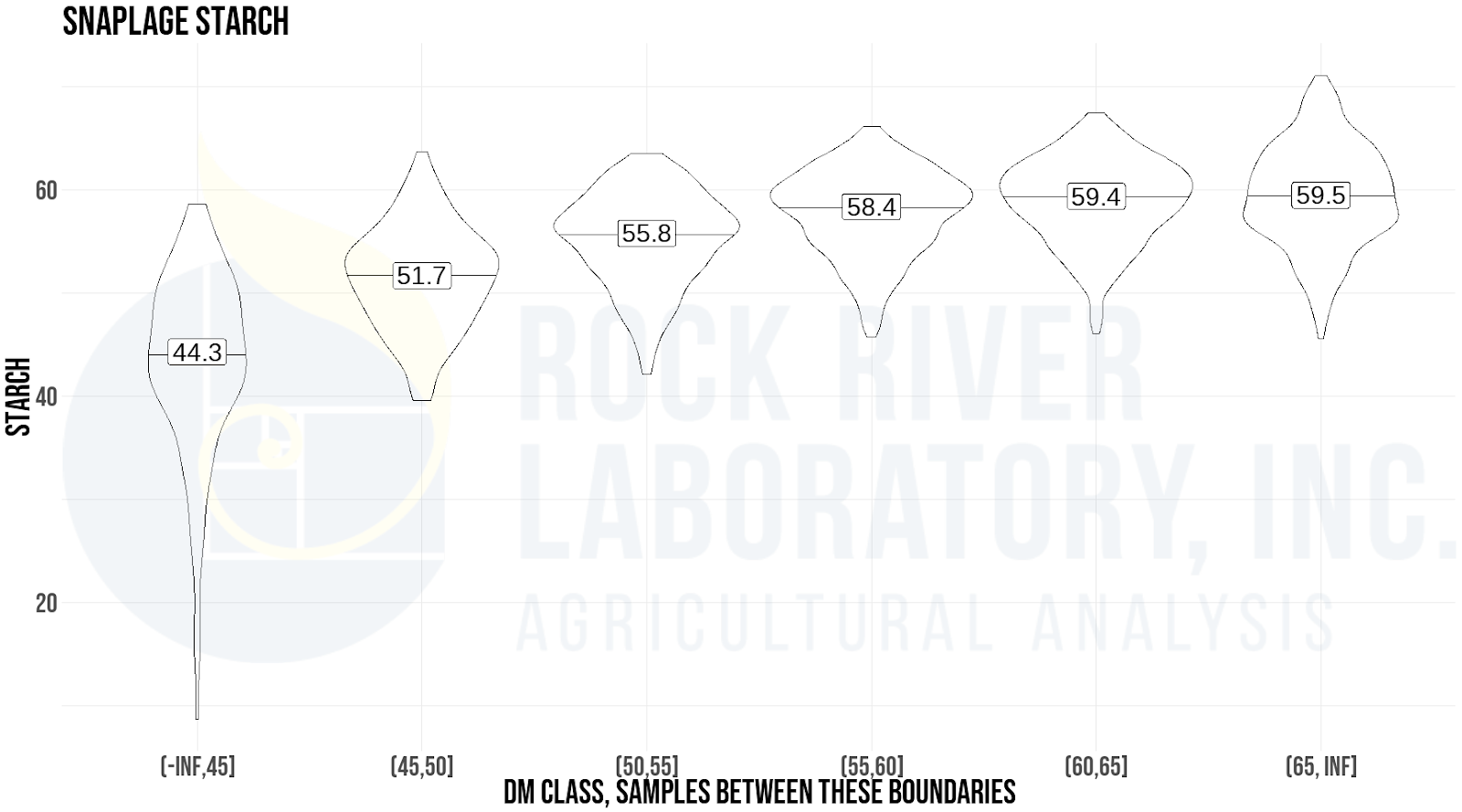

As corn advances toward the black layer, the grain continues to deposit and accumulate starch content. This is evident in Figure 1, where Rock River Laboratory data details that starch content in snaplage increases up to the point that snaplage reaches about 60 percent dry matter or 40 percent moisture.

Goeser shares, “at this point, the grain has reached black layer and the starch content is determined. Think of black layer like putting the cork in a bottle - nothing more can be added.”

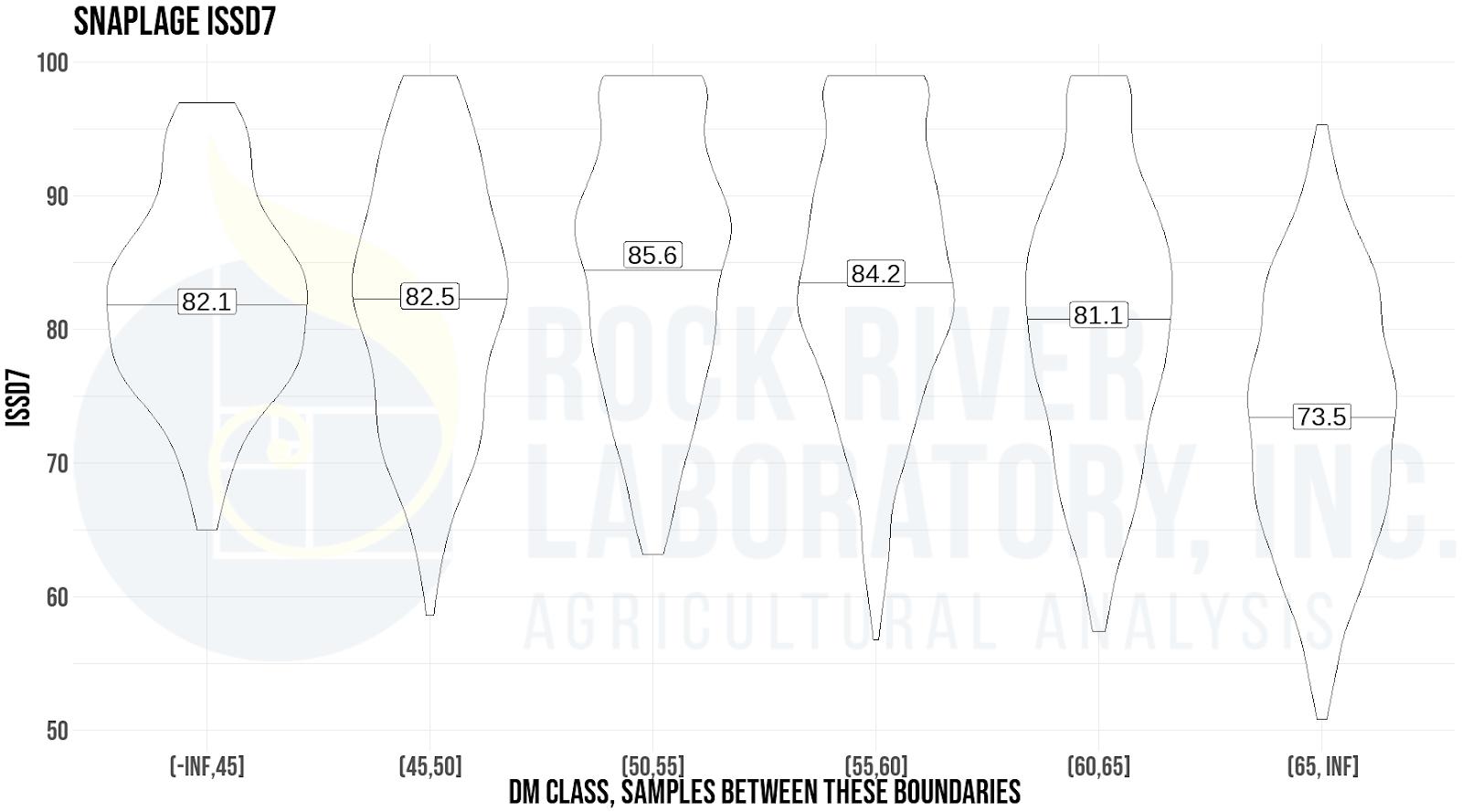

Beyond starch, one of the real nutrition benefits of snaplage ties into exceptional rumen starch digestibility potential. As mentioned previously, both kernel maturity and adequate moisture interact to affect rumen starch digestibility potential in snaplage.

Goeser further explains, “as the grain in snaplage advances to black layer maturity, the starch becomes increasingly harder in the endosperm, and the lesser moisture content in snaplage also renders the chopped material less likely to aggressively ferment in the bag or silo.”

The relationship between moisture and rumen starch digestibility of snaplage can be visualized in Figure 2.

In Figure 2, it’s apparent that rumen starch digestibility drops off as snaplage eclipses 60 percent dry matter, or less than 40 percent moisture, and the optimal starch digestibility for snaplage appears to be around 45 percent moisture.

“Tying this observation back into the starch content observations from Figure 1, roughly 45 percent moisture is also the point at which snaplage appears to reach maximum starch content,” states Goeser. “Monitor moisture and kernel maturity to balance starch content and digestibility in your snaplage. Harvesting snaplage between 40 and 50 percent moisture appears to be the sweet spot to optimize snaplage starch content and digestibility.”

He also suggests preserving high-quality feed with a research-backed bacterial inoculant or chemical-based preservative to ensure this valuable crop maintains optimum feeding value through to feed-out. “Corn silage, snaplage, and high moisture corn are also prone to yeast growth, heating, and aerobic instability issues, so a snaplage preservation strategy that enhances aerobic stability upon feed-out is a great idea.”.

With corn grain prices in excess of $5.00 per bushel, reviewing such data observations and planning with an agronomist, nutritionist, and harvesting crew can put any farm in the position to succeed with this popular feed.

Founded in 1976, Rock River Laboratory is a family-owned laboratory network that provides production assistance to the agricultural industry through the use of advanced diagnostic systems, progressive techniques, and research-supported analyses. Employing a team of top specialists in their respective fields, Rock River Laboratory provides accurate, cost-effective, and timely analytical results to customers worldwide, while featuring unsurpassed customer service.