The butterfat found in milk carries the flavor consumers have grown to savor when eating dairy products. However, the free fatty acids also found in milk can quickly become the enemy of those great-tasting dairy products. Even though these free fatty acids are naturally occurring in milk, they represent a small proportion of milk fat (less than of 0.1%). When their levels climb over 1.2 millimoles per 100 grams of fat bad things happen — off flavor, rancidity, reduced foaming ability, and inhibited milk fermentation. The latter impacts cheesemaking.

Hannah Woodhouse, a Ph.D. candidate at the University of Guelph, together with her adviser, David Kelton, looked to discover the reasons why some dairy herds have elevated free fatty acid levels. The long-term goal of the research project would be to minimize the causes that lead to higher levels of free fatty acids floating in milk. That, in turn, could improve both flavor and dairy product consumption.

Digging a bit deeper

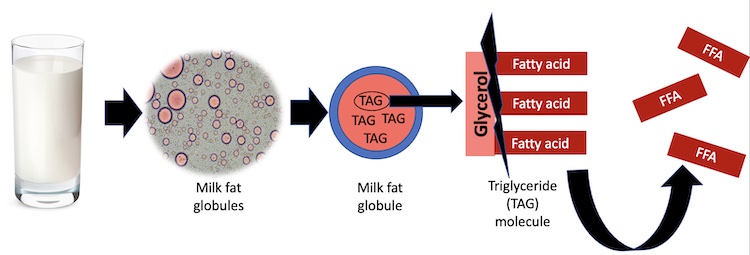

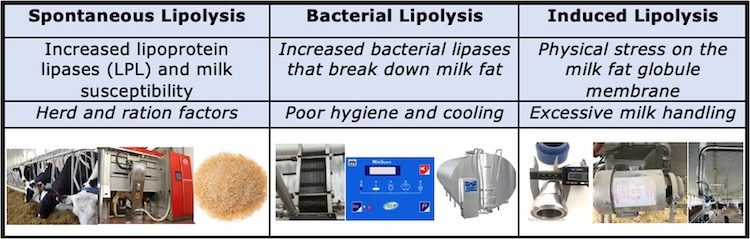

Milk fat globules are the foundation for milk fat. These milk fat globules have an outer membrane that acts as a protective casing. Inside that protective membrane are triglycerides that consist of a glycerol molecule and three fatty acids. When a milk fat globule gets broken down via a process that scientists call milk fat lipolysis, the glycerol molecule is separated from the three fatty acids. That’s when we get free fatty acids in milk. When free fatty acid levels climb over 1.2 millimoles per 100 grams of fat, milk quality becomes compromised.

To learn the why of the free fatty acid fallout, Woodhouse and her colleagues conducted a study on Canadian dairy farms located in Ontario and British Columbia. In all, the Guelph team looked at 300 on-farm bulk tanks and tracked several on-farm practices on herds that milked cows in tie stall barns, automated milking facilities, and parlors.

The overall study free fatty acid level was 0.84 millimoles per 100 grams of fat. While 90% of the Canadian dairy farms in the study had normal free fatty acid levels (less than 1.2 millimoles per 100 grams of fat), 10% of the herds had levels over this. None of those herds with elevated levels were farms with a milking parlor. So, what contributed to higher free fatty acid levels?

Milking frequency topped the list

Robot herds tended to have the greatest levels of free fatty acids if cows were milked, on average, more than three times per day. Woodhouse theorized that there wasn’t enough time in the fat synthetization process to create a wholly intact milkfat globule.

“Set a maximum number of visits for the robotic milking system,” advised Woodhouse, who grew up on a dairy farm. “Robotic milking systems allow for individualized settings. Limit the number of visits for late lactation and low-yielding cows since those are the ones with the most susceptible milk,” she continued while speaking at the 62nd annual National Mastitis Council meeting in Atlanta, Ga.

The reduced milking frequency also could be deployed in tie stall herds as those on three times per day milking schedules also had higher free fatty acid levels when compared to herds milked two times per day. Just like the robot herds, late lactation and low-yielding cows could be milked twice per day. Again, there was no difference for cows milked either twice or three times a day in milking parlors. She also noted the importance of equalizing milking intervals for conventional milking systems.

Milk filters and precooling matter

If a dairy is milking three times a day, the filter should be changed three times a day. That recommendation stands for every farm no matter if they are milking in tie stalls, parlors, or with robots. That was another key finding by the University of Guelph researchers. Among the study’s nearly 300 farms, 24 of the farms milked cows three times a day but changed their filters two times per day. “More often than not, those herds had elevated free fatty acid levels,” shared Woodhouse. The theory behind this is that an increase in bacteria levels from the unchanged filters can contribute to milk fat breakdown. Dirty filters are also less porous and can add stress on the milk fat globules as they pass through, which can in-turn result in lipolysis.

Also contributing to milk fat breakdown by bacteria to yield higher free fatty acid levels is the absence of precooling on a farm. Precooling can include a plate cooler, while some larger dairies also utilize fast-acting chillers. “None of the farms with chillers had free fatty acids over 1.2 millimoles per 100 grams of fat,” shared Woodhouse. Without precooling, researchers theorized that longer agitation times in the bulk tank due to an increase in cooling time also led to lipolysis and freed those fatty acids from their glycerol backbone. Again, installing a plate, tube or kube cooler or chiller as a precooling option would remedy this situation.

Lastly, the Canadian researchers found that some herds supplementing high levels of fat in rations also had elevated free fatty acids in bulk tank milk. Along with seasonality factors, that’s a situation with further monitoring.