We tend to assume that in automated milking systems (AMS), cows spend little to no time waiting to be milked compared to cows that stand in a holding area, waiting to be milked in the parlor. That’s because they can choose when to access the milking robot without leaving their home pen. No matter what milking system is used, we know that long periods of standing are detrimental to cow health and comfort, increasing their chance to develop lameness and hoof lesions.

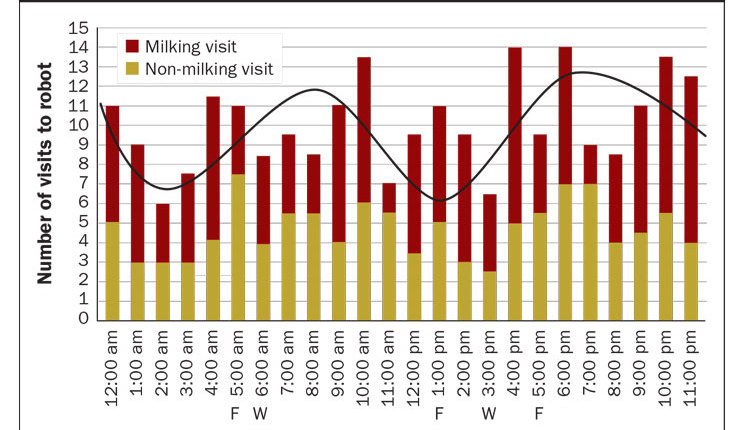

Our team explored cow behavior in free-flow and guided-flow barns with AMS. In this article, we’ll focus on the findings from an observational study where we used video analysis from 40 cows over two days in one commercial free-flow AMS herd (Figure 1). We were curious to know how long cows waited to be milked, which factors impact waiting time, and what choices cows make when they are unsuccessful in accessing the milking robot.

Wait times varied

The free-flow herd in our study milked 180 Holsteins with three robots and averaged 95 pounds of milk per cow per day over a six-month period. The study pen consisted of a mixed-parity group of 59 cows with one robot installed on the side of the barn, parallel to the pen. There was a fetch pen which remained open throughout the day so cows could enter voluntarily but was closed three times a day when cows were manually fetched into the pen. The pen had a three-row layout with 60 deep-bedded sand stalls and grooved concrete alleys.

On average, cows visited the robot to wait to be milked six times per day and spent 15 minutes waiting per visit for a total waiting time of 90 minutes per day. This daily waiting time is shorter than what is reported for conventional parlor milked herds, but what was surprising was the large variation in waiting time among cows. Some cows only waited five minutes per day to be milked while other cows waited over five hours per day!

Parity, days in milk, and the interaction between the two had an impact on daily waiting time (Figure 2). First parity cows in early lactation had more frequent and longer visits to the robot waiting area, resulting in long waiting times (around two hours per day). But in late lactation, this behavior gradually became more like that of older cows, with fewer and shorter visits to the waiting area, resulting in shorter waiting times (about one hour per day). It is likely that competition and inexperience played a role in the long waiting time observed in first parity cows early in lactation.

Another factor that had an impact on daily waiting time was related to the voluntary and repeated use of the fetch pen throughout the day to access the robot. Cows that showed this behavior had, on average, 40 minute longer waiting times and fewer visits to the waiting area compared with cows that rarely entered the fetch pen. Even among first parity cows, those that voluntarily and repeatedly used the fetch pen waited, on average, about one hour per day longer than those that did not.

If cows aren’t milked when they want to be, a free-flow traffic design gives them freedom to choose from a variety of alternative activities such as lying down, drinking, or eating. So, what choice do cows make when they fail to access the robot?

Most of the time, cows chose to continue to stand idle in the alley or in a stall on the lookout for an opportunity to get milked. As time passed by, about 25% of the time, cows moved to the feedbunk or a water trough, but there was a much higher probability that cows would either continue standing in the alley, in a stall, or return to the waiting area. This suggests that the desire to be milked continues to influence behavioral decisions after a failed attempt to access the robot.

The longer cows waited to be milked, the less time they had to rest. On average, cows spent 10 hours and 50 minutes per day lying down, with a wide variation from five to 16 hours per day. Cows that had long waiting times (over two hours per day) tended to spend an average of one hour and 40 minutes per day less lying down compared to cows with shorter waiting times (less than two hours per day).

Keep cows milking

There are four ways to mitigate competitive behavior through management and design.

1. Robot entry

Cows that voluntarily used the fetch pen tended to wait longer because they were at a disadvantage when competing with cows outside of the fetch pen for access to the robot. Cows in the main waiting area exerted pressure over cows in the fetch pen by forcing their way past the end of the swing gate.

This could be improved by having gating at the entryway to protect the neck and shoulder of the next cow in line (Figure 3). This would discourage dominant cows from displacing subordinate cows by limiting their interaction to the rear of the waiting cow.

2. Robot exit area

After milking, some cows exiting the robot displaced cows waiting in line to gain access to the robot. In some cases, this displacement was clearly an aggressive interaction from dominant cows, but sometimes it was due to limited space in the waiting area during periods of high robot visit frequency. An AMS layout where cows exit away from the robot entrance and are not able to interfere with cows waiting in line could prevent this behavior.

3. Stocking density

An adequate stocking rate of cows per robot may lessen the dominance effect, reduce standing time, and lessen the impact of failed access attempts.

4. Grouping strategies

Adoption of grouping strategies to reduce competitive behavior, especially toward primiparous cows, along with training heifers to use the robot before calving may reduce waiting times.