The author is a nutrition and management consultant with Progressive Dairy Solutions based out of California.

Once a modernized and well-maintained forage harvester is set up and operating properly, it is capable of processing outstanding corn silage.

Forages and all feedstuffs account for the greatest percent of all expenses to produce milk. This year, we could see that number rise to upwards of 70 percent. At all times, but especially as costs creep up, it is even more important to ensure the highest returns from the nutritional investments in our milking herds.

Ensuring a high return means capturing the most value from every feed purchase and removing the hurdles that limit cows' ability to produce milk. This point rings especially true for feeds like corn silage. Dairymen need to work with their nutritionists and crop consultants to understand what influences the complete digestibility of corn silage (stover and grain portions together), how the digestibility can be measured, and how the digestibility affects ration costs?

Make the most of your feed

Nutrients from corn silage are diverse. The stover offers much needed fiber and grain provides starch. The starch is an important, high-volume energy source for dairy cows. For better or worse, as a matter of divine creation, the starch is embedded in the kernel under a prolamin protein matrix and is hydrophobic. These two characteristics of the kernel can make starch difficult to digest unless processed properly.

Without proper corn silage processing, valuable nutrients will pass through the cow and will not be fully digested. Properly processing corn silage is critical for today's modern dairy businesses, and it is completely dependent on the mechanics of the forage harvester and the motivation of the operator.

Poorly processed corn will lead to lower rumen and total tract starch digestibility, noted Ralph Ward, who heads up Cumberland Valley Analytical Services (CVAS). On the contrary, optimal processing greatly improves starch and other nutrient digestibility as well as the overall value of the crop by way of more nutrient availability, not to mention it reduces the need for further grain supplementation when formulating rations.

The quality of corn silage processing can be measured by determining the Corn Silage Processing Score (CSPS), also known as Kernel Processing Score (KPS). The CSPS describes the amount of starch in the corn silage that is readily available to cows. It is reported in three different levels:

There were 204 silage samples collected from a new Krone 750 C BIG X forage harvester set up with multiple KP styles and gaps at 0.5, 1.0, 1.5, 2.0 and 3.0 mm. All samples were sent to CVAS to obtain the CSPS as well as nutrient content.

The results showed that, regardless of processor style, samples taken from the machine set at gaps of both 1.0 mm and 1.5 mm averaged 69.2 (n=162) on the processing score. Meanwhile, all other samples (gap of 0.5, 2.0 and 3.0 mm) averaged just slightly lower with a CSPS of 68.6 (n=46).

Additionally, nutrients and plant composition were assessed in the study to determine the impact on CSPS. The study also included a comparison of early (before September 15) versus late (after September 15) season corn crops. Within each subseason there are factors that influenced the processing, such as the energy, starch and dry matter, which all lead to one extent or another a higher CSPS. Ultimately, these factors greatly improved the value of the silage as well as the usability of the feed because the highly adequate processing allows nutrients to be more readily available to the cow.

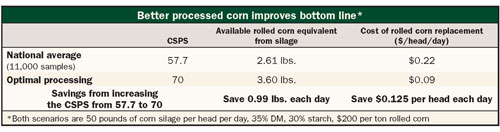

The CSPS has a substantial impact on the overall value of corn silage simply because the higher the CSPS, the more starch becomes available to the cow. When silage is poorly processed, the starch stays bound in the protein matrix and is unable to be digested . . . therefore it requires a higher amount of starch supplementation to the ration. Additional grain can take the shape of rolled, steamed flaked, high-moisture corn or earlage type products.

Alternatively, dairymen can save 12.5 cents per head per day by improving the CSPS from the national average of 57.7 to an optimal score of 70-plus so the cow can fully utilize the starch that is already in the silage. For a 250-head operation, that means a savings of over $11,400 each year at $200 per ton corn replacement product.

Expose the plant, too

Just exploding the kernel is not all that should be expected from properly processed corn silage when the machine is set up and operated correctly; the stalks should be sliced and torn, as well. Processing is a tool to minimize feed cost and maximize health and production.

What it all boils down to is knowing the CSPS of the corn silage that is being harvested and ultimately fed. It makes a difference in the quality of feed and ultimately has a tremendous impact on the cost of the ration when the harvester is conscientious about the processing of silage. Remember, processing is not only about exploding the kernel but also about slicing and tearing the stover or stalk portion to reveal the inner stalk and maximize surface area, both vertically and horizontally.

Many factors go into achieving ultrahigh-quality corn silage; before investing in kits or aftermarket equipment and processors, this study reminded us about the importance of making sure you know the quality of processing the harvester is capable of doing when the equipment is properly set up and an ideal processor gap is set and maintained.

Click here to return to the Crops & Forages E-Sources

150210_85

Forages and all feedstuffs account for the greatest percent of all expenses to produce milk. This year, we could see that number rise to upwards of 70 percent. At all times, but especially as costs creep up, it is even more important to ensure the highest returns from the nutritional investments in our milking herds.

Ensuring a high return means capturing the most value from every feed purchase and removing the hurdles that limit cows' ability to produce milk. This point rings especially true for feeds like corn silage. Dairymen need to work with their nutritionists and crop consultants to understand what influences the complete digestibility of corn silage (stover and grain portions together), how the digestibility can be measured, and how the digestibility affects ration costs?

Make the most of your feed

Nutrients from corn silage are diverse. The stover offers much needed fiber and grain provides starch. The starch is an important, high-volume energy source for dairy cows. For better or worse, as a matter of divine creation, the starch is embedded in the kernel under a prolamin protein matrix and is hydrophobic. These two characteristics of the kernel can make starch difficult to digest unless processed properly.

Without proper corn silage processing, valuable nutrients will pass through the cow and will not be fully digested. Properly processing corn silage is critical for today's modern dairy businesses, and it is completely dependent on the mechanics of the forage harvester and the motivation of the operator.

Poorly processed corn will lead to lower rumen and total tract starch digestibility, noted Ralph Ward, who heads up Cumberland Valley Analytical Services (CVAS). On the contrary, optimal processing greatly improves starch and other nutrient digestibility as well as the overall value of the crop by way of more nutrient availability, not to mention it reduces the need for further grain supplementation when formulating rations.

The quality of corn silage processing can be measured by determining the Corn Silage Processing Score (CSPS), also known as Kernel Processing Score (KPS). The CSPS describes the amount of starch in the corn silage that is readily available to cows. It is reported in three different levels:

- Inadequately processed corn silage has a processing score of less than 50

- Adequate processing has a score of 51 to 69

- Optimal processing has a score of 70 or greater

- Properly processed silage results in slicing the crop horizontally and vertically for maximum surface area exposure in addition to exploding the kernels.

- To determine the best practice of machine operation and machine setup to maximize the nutritional value without adding aftermarket processors or kits to the forage harvester.

- Evaluate how producing a highly digestible and optimally processed silage affects the cost of a ration.

There were 204 silage samples collected from a new Krone 750 C BIG X forage harvester set up with multiple KP styles and gaps at 0.5, 1.0, 1.5, 2.0 and 3.0 mm. All samples were sent to CVAS to obtain the CSPS as well as nutrient content.

The results showed that, regardless of processor style, samples taken from the machine set at gaps of both 1.0 mm and 1.5 mm averaged 69.2 (n=162) on the processing score. Meanwhile, all other samples (gap of 0.5, 2.0 and 3.0 mm) averaged just slightly lower with a CSPS of 68.6 (n=46).

Additionally, nutrients and plant composition were assessed in the study to determine the impact on CSPS. The study also included a comparison of early (before September 15) versus late (after September 15) season corn crops. Within each subseason there are factors that influenced the processing, such as the energy, starch and dry matter, which all lead to one extent or another a higher CSPS. Ultimately, these factors greatly improved the value of the silage as well as the usability of the feed because the highly adequate processing allows nutrients to be more readily available to the cow.

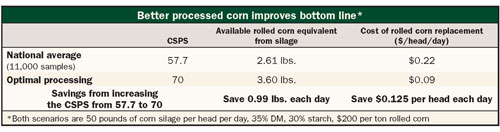

The CSPS has a substantial impact on the overall value of corn silage simply because the higher the CSPS, the more starch becomes available to the cow. When silage is poorly processed, the starch stays bound in the protein matrix and is unable to be digested . . . therefore it requires a higher amount of starch supplementation to the ration. Additional grain can take the shape of rolled, steamed flaked, high-moisture corn or earlage type products.

Alternatively, dairymen can save 12.5 cents per head per day by improving the CSPS from the national average of 57.7 to an optimal score of 70-plus so the cow can fully utilize the starch that is already in the silage. For a 250-head operation, that means a savings of over $11,400 each year at $200 per ton corn replacement product.

Expose the plant, too

Just exploding the kernel is not all that should be expected from properly processed corn silage when the machine is set up and operated correctly; the stalks should be sliced and torn, as well. Processing is a tool to minimize feed cost and maximize health and production.

What it all boils down to is knowing the CSPS of the corn silage that is being harvested and ultimately fed. It makes a difference in the quality of feed and ultimately has a tremendous impact on the cost of the ration when the harvester is conscientious about the processing of silage. Remember, processing is not only about exploding the kernel but also about slicing and tearing the stover or stalk portion to reveal the inner stalk and maximize surface area, both vertically and horizontally.

Many factors go into achieving ultrahigh-quality corn silage; before investing in kits or aftermarket equipment and processors, this study reminded us about the importance of making sure you know the quality of processing the harvester is capable of doing when the equipment is properly set up and an ideal processor gap is set and maintained.

150210_85