The author is a ruminant nutrition extension specialist in the department of animal and dairy sciences at the University of Wisconsin-Madison.

Farmers make many critical decisions prior to, during, and after harvesting forages. These decisions directly impact how well forage will ferment and be preserved for future feedout. Adding to this unique biological process, weather events and specific crop characteristics make the fermentation process of each silo one-of-a-kind.

Selecting the right silage inoculant to modulate fermentation, according to each scenario, ensures adequate fermentation and helps safeguard the silage investment. Each extra pound of dry matter preserved stretches hard-earned dollars and improves the land use efficiency for milk production. With that in mind, here are some tips to consider prior to picking the inoculant that best fits your crop.

Removing the air

In a nutshell, filling and sealing the silo as fast as possible while limiting the amount of oxygen remaining in the silage mass is critical to silage preservation. Anaerobic epiphytic (native) bacteria fermentation requires the absence of oxygen. The less oxygen that remains in the silo, the faster the desired fermentation begins. Bacteria ferment water-soluble carbohydrates (sugars) into lactic and acetic acids and pH drops until silage becomes stable. When excessive oxygen remains within the silage mass, undesired microorganisms such as yeasts proliferate at the expense of valuable substrates.

Practices that improve silo density or reduced porosity go a long way. A very simplistic definition of porosity is the gap space between the forage mass filled with air (including but not limited to oxygen). Greater packing density and reduced porosity improves fermentation and diminishes storage losses. Adequate layer thickness while packing, tractor weight, delivery rate, and harvesting forages not too coarse or dry reduces silo porosity.

But even well-packed and dense silage piles could ferment inadequately. Crop-related factors like moisture content, buffering capacity, availability of water-soluble carbohydrates, and the amount and type of epiphytic bacteria population all influence silage fermentation.

Silage inoculants contain bacteria that take over the fermentation process and shift silage fermentation toward a desired pattern for optimum preservation. This may help in situations where the epiphytic bacterial population is unable to dominate the fermentation process.

Bacteria commonly found in silage inoculants can be divided into two main groups: homofermentative and heterofermentative. These inoculants differ in what fermentation end products are produced. Given the differences among crops, management practices, and weather, it is advised to use a product designated for the individual conditions of your silage.

Boosting the initial fermentation

Homofermentative bacteria or those made with a single bacterial end product typically have lactate as their main fermentation end product. Silage inoculants containing this type of bacteria accelerate the pH drop as lactic acid is a stronger acid than acetic acid. A fast reduction in pH prevents growth of undesired microorganisms and reduces protein degradation once ensiled.

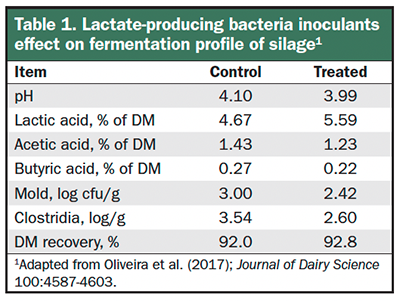

Table 1 exemplifies the potential effects of inoculating silage with homofermentative microbial inoculants. This type of inoculant may be a perfect fit in scenarios where the epiphytic bacterial population is low, the crop buffering capacity is high, or the forage is too wet.

For example, in legume silages, the high crude protein levels lead to greater ammonia-N concentrations. Ammonia-N is a natural buffer and does not allow pH to drop fast, making the silage more susceptible to clostridial fermentation.

Another scenario would be a farm feeding from multiple silos each year. Perhaps adding this type of inoculant to silos being open over the winter would ensure adequate short-term fermentation.

Keeping silage stable at feedout

Silage loss on farm can be higher at feedout than during fermentation due to poor stability. Overall, the fermentation process determines how unstable the silage mass is while feeding. Aerobic stability is the length of time that silage lasts before heating or being spoiled after air exposure.

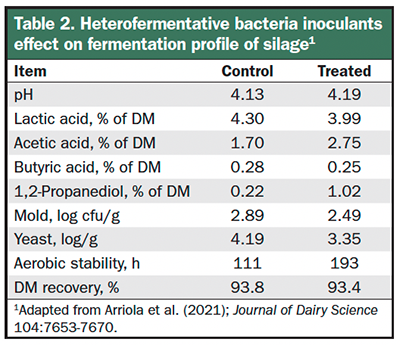

Heterofermentative bacteria or those with multiple bacterial end products, such as Lactobacillus buchneri, produce lactic and acetic acids and ethanol. Although these bacteria have a slower fermentation rate, these can convert lactic acid into acetic acid and 1,2-propanediol. See the example in Table 2.

Acetic acid has antifungal properties, and the silage will take longer to heat up after exposure to oxygen. This type of inoculant is suggested when ensiling crops rich in starch or in silos that will be fed during late spring and summer as during this time silage is prone to lower aerobic stability.

Although bacteria in the silo ferment sugars, yeasts can ferment not only sugars but also starch. Thus, forages with greater starch concentration such as corn tend to be more prone to spoilage after air exposure.

Practices that allow for air infiltration into the silage material also reduce aerobic stability. Some commonly observed practices include an uneven silo face, slow rate of removal, and plastic removed from a given section of the silo too far in advance.

Weather also plays a major role in aerobic stability. Silage fed during the summer or in warmer climates is more prone to reduced aerobic stability. Inoculating silage with heterofermentative fermentative inoculants would be ideal under these conditions.

Treating silage with inoculants preserves more nutrients and dry matter, makes the silage process more efficient, and safeguards the silage investment. But inoculating silage does not replace adequate harvesting practices and silo management. Specific crops and scenarios require different types of bacteria and application rates. Make more informed decisions based on research trials conducted by independent research parties and not based solely on prices.