The authors are with Quality Milk Production Services, Cornell College of Veterinary Medicine.

The amount of organic matter present in the sand directly determines cleanliness. Put another way, high-quality sand is nearly free of organic matter.

Why do we want sand to be free of organic matter?

Mastitis pathogens require both nutrients and moisture to grow, and when found in sand, mastitis-causing pathogens flourish. Sand bedding that retains urine and manure may become an even greater threat to udder health given the elevated pathogen load in the sand. Manure may seed bedding materials with large numbers of environmental mastitis pathogens.

Clean sand is an ideal bedding for dairy cattle, and extremely low levels of organic matter and small numbers of microorganisms are manageable. High-quality sand also drains well by wicking away moisture and allowing the bedding to dry quickly.

Ideally, sand bedding should be washed and graded before delivery to a farm. Washed sand (masonry sand or washed concrete sand) will be virtually free of organic matter and have a more uniform particle size, adding to the overall comfort characteristics of the bedding.

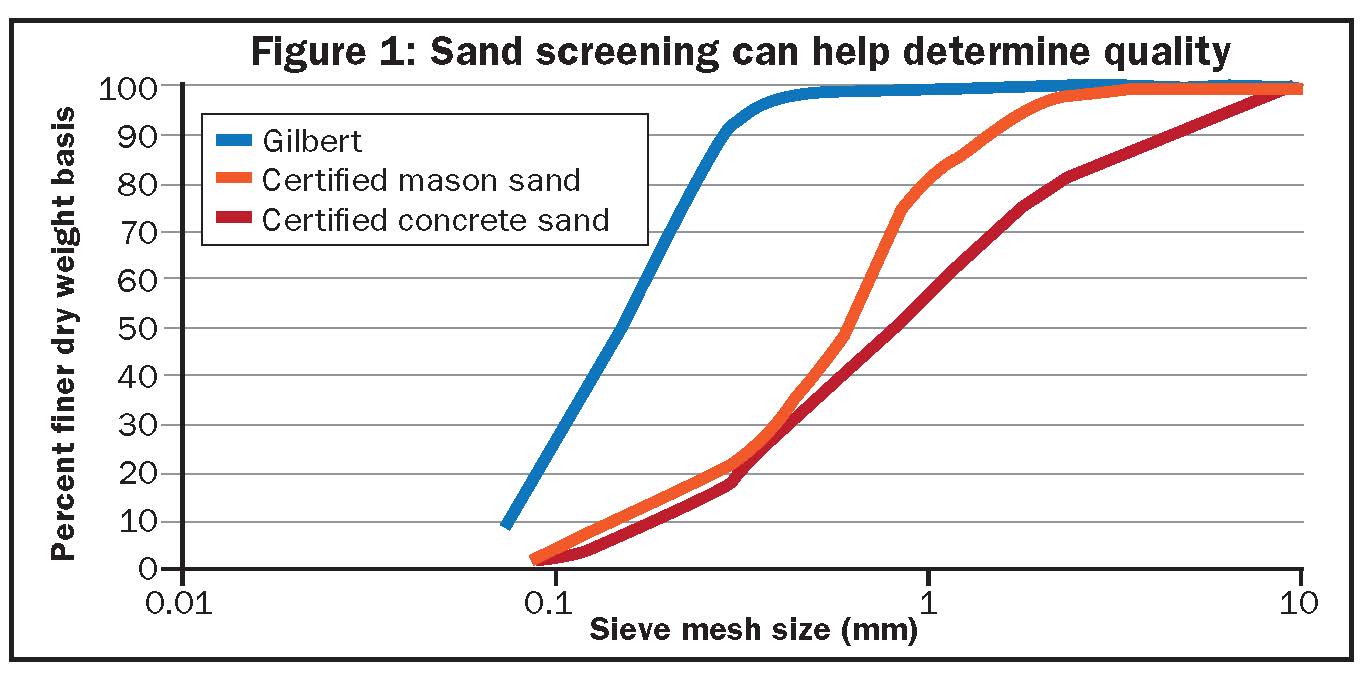

Research from The Ohio State University showed the most desirable grades of sand have two common characteristics. First, almost all of the sand grains are 0.1 to 2.0 mm (millimeters) in size. Second, the sand particles are uniformly sized, meaning that the majority of sand particles are similar in size and within the range of 0.1 to 2.0 mm.

These two characteristics largely determine if a material will drain properly and maintain a “giving” texture for a comfortable stall bed surface. The uniformity in size is akin to a “Ball Play Pit” for children. The uniform size of the balls provides a soft, flexible surface to play on.

Quality Milk Production Services and the Animal Health Diagnostic Center at Cornell University have added sand sieve (particle size), dry matter, and organic matter analysis to its sand bedding evaluation. This is in addition to the standard environmental microbial analysis, which provides a total microbial count of the sample along with a summary of the major environmental mastitis-causing organisms.

The sand sieve analysis appears as a graph of particle size of the test sample with two reference samples (washed masonry sand and washed concrete sand), which are considered to be suitable bedding materials for lactating cows. When conducting the analysis (see Figure 1), a table listing the contribution of each particle size is also part of the report. The new sand analysis evaluates the suitability of current sand bedding materials and screens new sand sources for the appropriate recycled sand characteristics.

What makes poor sand?

Sand bedding with an abundance of small particles (silt and clay) will compact more readily. Sand that becomes compacted in the stall bed is detrimental to drainage and is less comfortable for the animals to rest on.

A high level of fine particles in sand is less cost-effective as fines are lost during the recycling process. Fine particles in sand also have a greater tendency to “stick” to the cow’s body, especially the udder and teats.

Sand with an excessive amount of fine particles is not uncommon and the result may be sand contamination of milk meters and bulk tank milk. We have seen bulk tanks and milk silos with an inch or more of sand at the bottom of the tank when emptied. Some veterinarians with hoof health expertise and hoof health specialists believe sand particles of 3 mm or greater in size raise the risk for sole injury and/or lameness.

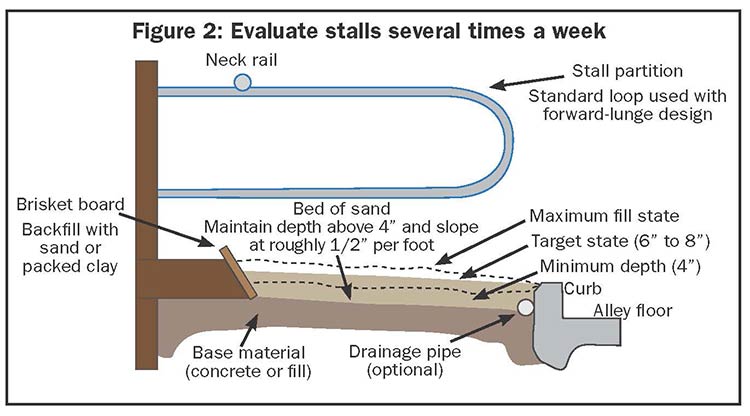

Sand also has characteristics that promote cow comfort, an often overlooked feature of sand as a bedding material. As with any bedding, material stall design and bedding maintenance are critical to the success of bedding management. Sustaining an appropriate level of bedding in the stalls is vital to maintaining cow cleanliness and comfort.

Evaluate stalls several times weekly using the guideline in Figure 2. Sand bedding is also a good conductor of heat, which adds to cow comfort during periods of heat stress. It offers an additional incentive for cows to lie down during times of heat stress, increasing resting time.

In summary, sand bedding analysis includes the environmental microbial report, sand sieve analysis, dry matter, pH, and organic matter. The values in the sand report will provide additional information for selecting high-quality sand as the main dairy cattle bedding source.

The ProDairy website has several excellent articles on the use of sand bedding for tie stall and freestall facilities. Go to http://on.hoards.com/PRO-DAIRY.