This year has brought another summer of interesting weather conditions for alfalfa growers. From winterkill to rain to dry weather, we’ve seen it all and it all makes sampling even more important.

Much of the alfalfa hay sold in the U.S. is defined by its relative feed value (RFV), which is determined by laboratory analysis. Discrepancies sometimes arise when the laboratory reported RFV value is not as the grower, seller, or buyer anticipates. When this happens, it raises the question, “What went wrong?”

In alfalfa hay, acid detergent fiber (ADF) and neutral detergent fiber (NDF) are almost perfectly correlated. If you know one, you can with reasonable certainty predict the other. As the leaf to stem ratio in an alfalfa forage changes, both measures of fiber generally move up or down proportionately impacting the relative feeding value (RFV) calculation. For every 1 percent change in NDF (and by relationship ADF), there will be a change in RFV of 6 to 10 units.

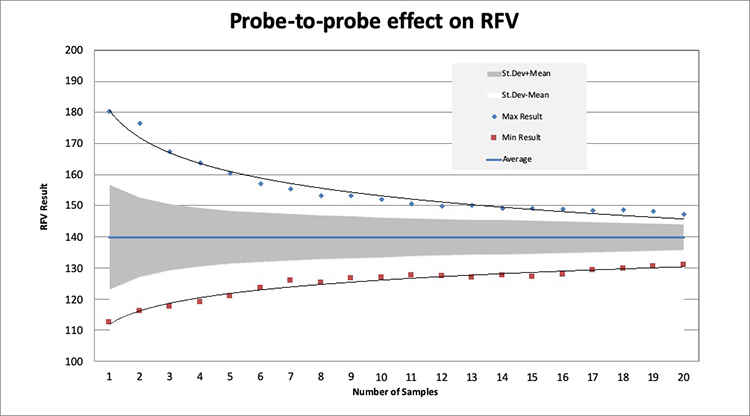

That’s critical to understand as field sampling is the greatest source of variation in fiber and thus RFV values. Probe to probe variation can be as much as 30 RFV points. If you are responsible for sampling, it is critical to take enough cores of a lot of hay to reduce this potential variation. The general recommendation is to take 15 or more cores to properly represent a lot of hay. The graph below shows the relationship between the number of cores taken and the range in RFV that may occur. In this data set, taking 15 or more cores reduced the range in RFV from plus or minus 17 units to less than plus or minus 5 units.

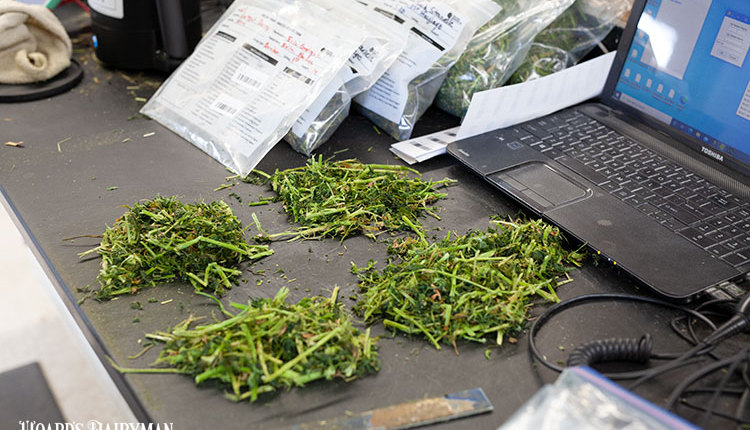

Once the sample is in the laboratory, the lab must grind all of the sample and properly homogenize the ground material before running either near-infrared (NIR) or chemistry analysis. Just as sampling in the field is impacted by the ratio of leaf to stem, this challenge also occurs in the laboratory. Check to see if your laboratory grinds all of the cored hay sample submitted and if the procedure is referenced in the laboratory report.

Sampling and lab recommendations for reducing RFV variation

- Sample close to the point of sale or point of feeding.

- Use a well-designed and proven probe design: a sharp tip 90 degrees from shaft, 3/8- to 3/4-inch bore.

- Sample at random.

- Sample center of butt ends, at 90 degrees and 12 inches to 18 inches deep.

- Take enough cores: The recommendation is a minimum of 15.

- Do not split samples. If you need splitting, ask your laboratory to grind, mix, and split.

- Use a lab that grinds the full sample and does not subsample. Be willing to pay for this service.

- When using laboratory chemistry services, make sure that the lab runs analyses at least in duplicate.

- Recognize that an RFV value is not an absolute value but has an acceptable range due to variation in sampling and lab handling and analysis.