The season for harvesting small grain silage is fast approaching. In some parts of the U.S., small grain silage may already be fermenting in the storage structure. The data below highlights important information for a successful small grain silage fermentation outcome for those contemplating harvest.

Successful silage making is dependent on several factors, some under the control of the grower and some not. Two key factors that influence silage fermentation are moisture and water-soluble carbohydrate level (sugar). The sugar level of the crop is significantly related to maturity and the amount of recent photosynthesis. Once cut, temperature and the amount of time spent wilting will impact the sugar remaining in the plant and available to support a productive fermentation.

The biggest bearing

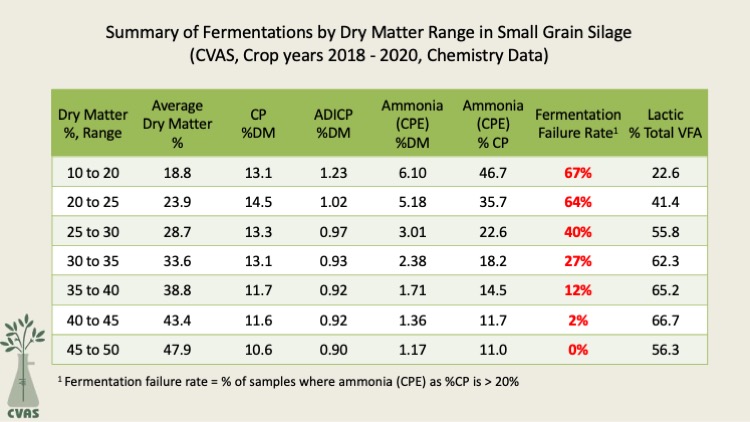

The moisture of the small grain plant at ensiling has the most significant bearing on fermentation. Data summarized by Cumberland Valley Analytical Services over the previous three harvest seasons demonstrates the importance of moisture on fermentation outcome.

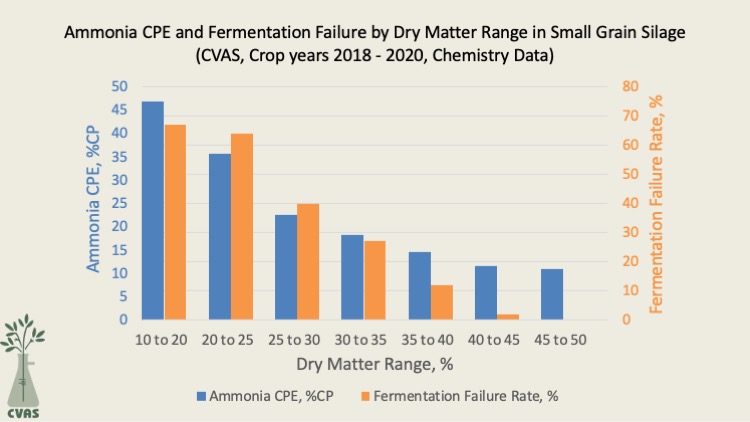

The most revealing characteristic of the fermentation outcome is the degree to which protein is conserved as true protein. We generally recognize this as silage with lower levels of ammonia. A significant relationship is observed between the level of ammonia on a crude protein equivalent (CPE) basis and the moisture level at ensiling. Generally, the higher the moisture level, the higher the level of ammonia generated by the fermentation. Further, if we define a “failure” in fermentation as one where ammonia on a crude protein equivalent basis exceeds 20% of the total protein, those silages with less than 35% dry matter (greater than 65% moisture) have more than one-third chance of fermentation failure!

An additional measure of fermentation success is lactic acid as a percentage of the total fermentation acids. The level of lactic acid as a percent of total acids is highest as silage is ensiled at moisture levels that also exhibit lower ammonia levels. Efficient fermentations are fermentations that conserve protein.

The data would advocate for ensiling small grain silage at 35% to 45% dry matter. Silage put up at wetter levels has a much higher probability of “fermentation failure.” This relationship is shown clearly in the graph below.

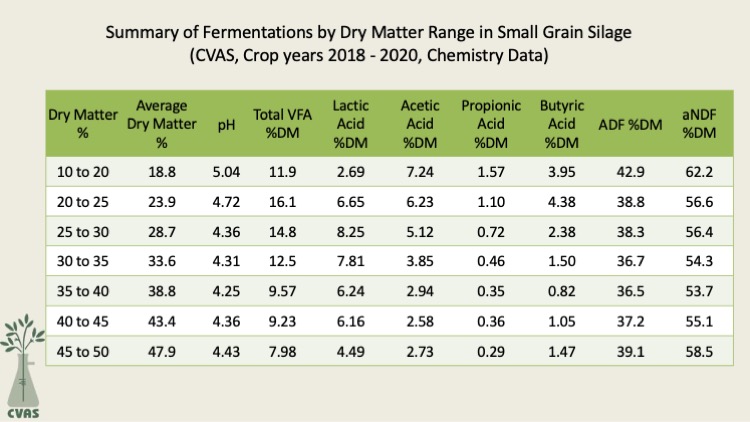

The data in the table below clearly demonstrates the impact of dry matter (moisture) at ensiling on fermentation outcome. Not only is protein conservation impacted, but all fermentation characteristics are affected. The pH is lowest in silages ensiled at 35% to 40% dry matter. Average butyric acid levels are lowest in this dry matter range as well.

Not too wet, not too dry

While it is crucial not to ensile small grain silage too wet, the grower needs to be careful not to ensile small grain silage too dry. Even though data shows that protein is better conserved at higher dry levels, it may not pack well in storage, the air is not as effectively excluded, fermentation may be prolonged, and heating may occur. For those silages that are harvested at the dough stage with higher starch levels, dry silage can lead to problems with yeast proliferation.

Small grain silage is a key forage component in many dairy rations. Small grain silage made correctly can support high levels of milk production. While silage-making factors are not always under the control of the dairyman, making silage at proper moisture levels will diminish the probability of fermentation failure and increase the probability of having a good fermentation outcome.