Embedded in the Class III and Class IV milk price formulas is the “make allowance.” It’s supposed to cover the cost of processing milk into bulk dairy products. The last time these processing costs were adjusted was 2008, and the formula was based on data from the 2005-to-2006 era.

Mark Stephenson, director of dairy policy analysis at the University of Wisconsin, was tasked with surveying plants to get an idea of how costs have changed, and he published the numbers recently. As expected, costs have climbed over the past 15 years, although the increases are bigger than what I expected to see.

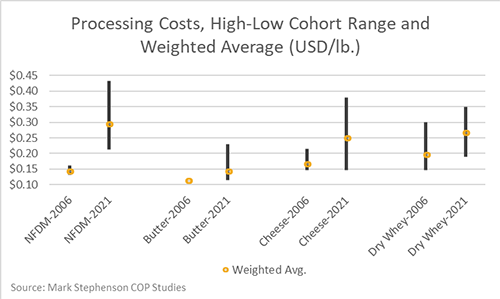

When possible, Stephenson split the costs into high-cost and low-cost groups and calculated a volume weighted average cost. The graph above shows the range between high-cost and low-cost plants, along with the weighted average from his survey back in 2006 and the paper he just published. The 2006 report mostly represents costs during 2005, while the new data roughly represents 2018. Of note, the newest report does not include any 2021 cost data, so an observer can’t blame the big increase in costs on pandemic-related inflation.

Costs are up an average of 56% between the two surveys, with the high side of the range up even more. There were some changes in methodology between the two surveys. In addition, the sample of plants is different between the two time periods. With that in mind, this latest report isn’t a direct comparison and some of the increase in costs may be due to methodology changes.

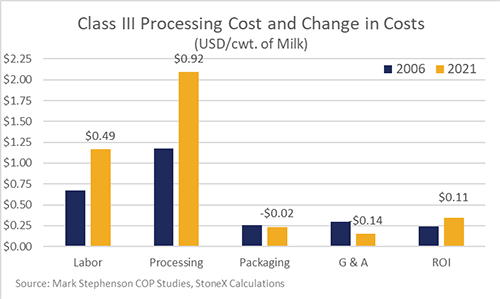

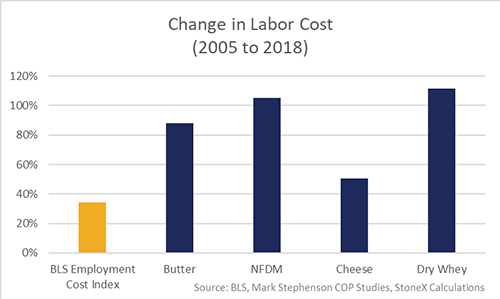

Most of the cost increase was due to labor and processing costs. Packaging, general and administrative, and return on investment costs were mixed and represented less than 20% of the total cost. The higher labor costs are pretty easy to understand, but I found the Employment Cost Index from the Bureau of Labor Statistics, and that index only increased 34% between 2005 and 2018. The surveyed labor costs for dairy products were up 50% to 111% during that time.

The increase in labor costs seems high to me, but Stephenson notes that the lowest-cost cheese plants are achieving labor costs on a per-pound basis of cheese that are lower than in 2005. On the flipside, the cost of labor at the high-cost plants has doubled. Large, new plants are more labor efficient. However, when it comes to butter/powder plants, we haven’t seen many new plants built, so that might explain the roughly 100% increase in labor costs for butter and nonfat dry milk (NFDM).

The other big line-item change was the jump in nonlabor processing costs. Utilities are included in this category, but they represented less than 10% of the category costs. I’m not sure exactly what else falls into this category, but I’m guessing equipment, depreciation, maintenance, cleaning chemicals, and possibly nonmilk ingredients such as rennet and salt. Costs in this category are up about 98%, which seems high, but certainly the cost of stainless steel and energy are up significantly since 2005.

What would it mean if the make allowances in the Class III and Class IV formula were raised?

An increase in the make allowance would push milk prices down relative to dairy commodity prices. For instance, with the current formula, $2.50 butter and $1.90 NFDM would result in a Class IV price of $24.76. If the processing costs from the latest survey were used for the make allowances, the Class IV price would drop by 94 cents to $23.81 and the plant would get to keep that 95 cents to cover the higher costs to convert the milk into butter and NFDM.

Two potential paths

With the way the system is currently set up, it is a zero-sum game between the processors and the farmers, which creates a contentious political fight. I think there are generally two paths to take to revise the make allowances in the Federal Milk Marketing Order (FMMO) formulas.

The first is the typical amendment process. That would begin with USDA conducting a preliminary investigation. Then, USDA would hold public hearings where processors, farmers, and the public could give comments and evidence. This evidence would include Stephenson’s survey results. After this data gathering process, USDA would issue a recommended decision and then issue a final decision. Farmers then vote on accepting the change, and if passed, the USDA issues a final order. This whole process took about a year in the past.

The other pathway would be congressional legislation. The formula to calculate the Class I price was changed in the last farm bill, so we could see the make allowances changed this way. Secretary Vilsack has said he is open to anything, but the whole industry needs to agree on it, and I doubt dairy farmers are going to be excited about their milk prices being adjusted lower by nearly $1 per hundredweight (cwt.).

I’m not sure how this is going to play out in the end. It does look like the make allowances need to be increased, but whichever path we go down, it will take at least a year to happen.