Many aspects of our dairy and ways of thinking have changed here at Hillcrest Farms since moving to a robotic milking system. The work is less physical and more mental. Once things calmed down after the transition, more than a year later, we started looking at the little things.

For instance, where is the sweet spot in milk production? What is the golden number of cows per robot? You can ask any robotic farm these questions, and most likely, you will get a different answer from each one. The reason for this is simple, though. It’s what works best for you.

Nutrition, dry matter intake, the make-up of the pellet, guided flow versus free flow barn design these are just a few of the things that will completely change the herd dynamics and “your sweet spot.” Before transitioning into robotics, we visited a lot of different dairies and got all kinds of opinions and “do’s and don’ts” for the robotic dairy world. But, at the end of the day, you find out real quick that every robotic dairy is different in many aspects, and what will work for you and what will not.

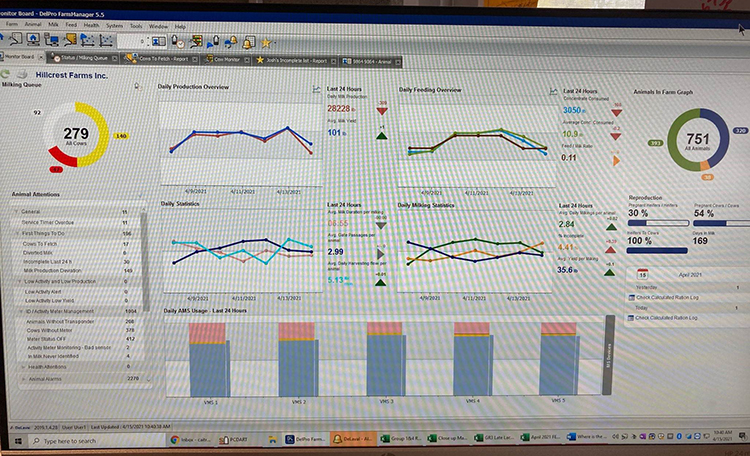

Our robots are located in a freestall barn with 364 stalls. We are milking 279 cows with 5 V300 robots. We have two different robot groups. The older cow group has three robots, and the first lactation cow pen contains two robots. We also have one group of 36 late lactation cows that are nearing the dry period; they are milked in our parlor.

We have issues that a lot of robotic dairy farms do not, including hot weather and stable flies. This will impact milk production here just about more than anything else.

Lately we have been trying to find that golden number of cows per robot. We were running around 64 cows per robot. At that point, we were averaging 84 to 85 pounds of milk per cow. We were told by a few people that we could run up to 70 cows per robot, while others told us 50 to 55 cows per robot. This seemed like a huge range to me, and I quickly realized that it was going to be one of those things that depends upon what works for you and your herd.

We have been slowly reducing our cow number per robot. We have gone from 64 cows per robot to 55 cows and all the sudden we are shipping the same amount of milk. The weather has started to bring on some heat stress here in Georgia and the stable flies are ramping up, so I honestly thought I would be seeing a reduction in milk due to lower cow numbers and the other variables. However, that definitely is not the case.

By reducing the number of cows per robot, we have given the more timid cows availability to the robots. Milkings per cow per day have gone from 2.55 to 2.9 or 3. We are now receiving more profitability with fewer cows, less feed, and higher milk production.

Mark and Caitlin Rodgers are dairy farmers in Dearing, Georgia. The Rodgers have a 400-cow dairy that averages 32,000 pounds of milk. Follow their family farm on Facebook at Hillcrest Farms Inc.