The author is a large-herd veterinarian based in Jerome, Idaho.

Even today, we can appreciate the expression. Who among us has not poured a cup of our favorite coffee or mixed an enticing cocktail and sat down, with the glass held gently before us in anticipation, only to have a cat jump in your lap and spill it? Or who hasn’t been driving and reached for a cup of Java and brought it to your lips, only to hit a bump in the road and have the hot brew spill in your lap?

Dickens’ phrase, along with others such as “The best-laid plans of mice and men often go awry” and “The road to hell is paved with good intentions,” mean essentially the same thing. We can make plans, taking the first or alpha step, but the outcome, the end or the omega, can turn out to be wildly different than what we envisioned. Murphy’s Law – if something can go wrong, it will –is usually alluded to humorously, but if an unforeseen and unanticipated result happens to you, it’s not so funny.

There are many examples of unforeseen consequences, “slips between the cup and the lip,” on the dairy. I dealt with one very recently, a blunder or mishap, that cost the dairy considerably in lost milk. It could have been prevented had the omega, the end result, been considered adequately beforehand.

I’m very proud of one herd in particular that I work with. They have high milk production, achieve great reproduction, and provide very good welfare and cow comfort. They are good managers, and “surprises” of any kind are few and far between. If I find any fault with them, it is that they tend to overcrowd, but they atone for this husbandry “sin” by successfully managing around it.

The manure says a lot

Reproductive health visits are a valuable opportunity for me to get a holistic view of the herd. Veterinarians, when they conduct reproductive exams, typically multitask. Simultaneously, we may be chatting away with you about your daughter‘s prowess on the high school basketball team and peering into our ultrasound goggles at a reproductive tract. As we have our arm in the cow, we are also alert to physiological data such as temperature and, very importantly, to how well the trillions of symbiotic gastrointestinal microbes are digesting the diet.

The cow’s manure, literally at our fingertips, is a sensitive and eminently available source for this vital and valuable information. Typically, manure quality, as assessed by me on every cow I enter, is uniform, properly textured, and of normal odor. On this particular visit, however, it was quickly evident that something was amiss.

While the cows appeared to continue to eat their total mixed ration (TMR) with gusto, things on my end told a different story. I was encountering whole corn kernels in abundance in every cow’s manure. I could also see and feel the kernels in the manure underneath my feet. None of this was evident from the feed alley side, of course.

In addition, I noted that cows resting in the freestalls had manure of widely varying consistency immediately behind them. It ranged from pools of loose manure, often watery and bubbly, to piles of unusually firm or “stacked” fecal matter. This was a big “red flag,” signifying something was wrong with the TMR or the cows. To make a long story short, the problem ultimately led to reduced feed intakes. This is milk that will never be reclaimed.

As I always do when presented with an unusual observation, I asked the owners that day, “What has changed?” In this case, they had just begun including corn silage from a new pile in the TMR. However, they had not tested it beforehand, either through forgetfulness or design, but had hoped that the analysis would be close enough to not affect digestion. This proved to be an expensive oversight or assumption.

Later analysis of the silage, both visually and chemically, showed a great difference between the pile used previously. It turned out that the kernel processor had been malfunctioning during harvest for this pile, and during the “shock and awe” of a busy harvest season the event had been forgotten.

The lesson from this slip-up is this: always be proactive and test feeds and reformulate before inclusion into your rations.

Design for cows and people

A second common area where neglecting to plan encourages unforeseen negative consequences is in barn and facilities design. Maternity and hospital areas are rarely, in my experience, crafted with sufficient veterinary input and involvement. If they were, we would see vastly different calving and hospital facilities than currently exist on many dairies. I have found that maternity and animal treatment stations seem to often be an afterthought, and are improvised or altered after an urgent need becomes manifest.

The basic elements of good calving and hospital facilities are that they address restraint, shelter from the elements, lighting, and hot water. Restraint that is safe for both staff and the patient mandates a gate or chute that is strong and allows efficient therapeutic interventions and also the safe and speedy removal of a cow should it go down.

These processing stations need hot water to properly warm intravenous fluids and drenches and to allow adequate cleaning and disinfection of implements. They need adequate lighting to ensure safety and treatment accuracy. Shelter from the elements improves worker and cow comfort and encourages task compliance and completion.

An important feature of freestall barns that is often overlooked and deficient, especially in the large, multi-hundred cow pens where I work, is that of suitable access from the alley to the pen itself. So-called “man holes” allow workers that are frequently in and out of pens, such as breeders, cow pushers, or vets, to move from the back to the front or vice-versa, without having to walk the complete length of the pen.

Running out of supplies such as hormones or a vaccine is common, and it is very tempting, if reloading involves a hundred yard run through manure or jumping over a headlock, to forego or postpone doing the remaining animals. Having sufficient and strategically-placed employee access points in large freestall pens saves time, boosts morale, and improves the odds of task completion.

A final issue

A third and final area where I frequently observe “slips” is when dairymen neglect to consider calving inventory or number of projected calvings. Most herds, unless they have consistent reproductive success, generate an oscillation or wave-form fluctuation in pregnancy numbers from month to month.

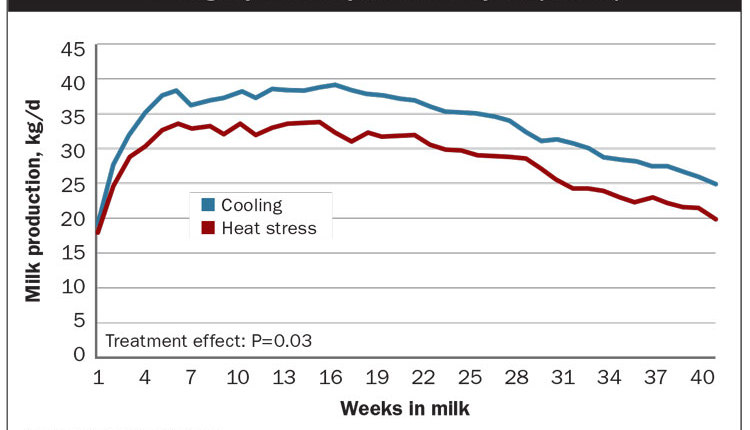

The swings can be considerable, especially after “hinge” seasons such as spring to summer (hot weather famously lowers conception rates) or fall to winter, where the cooler fall and winter weather reverses this effect and open cows thus get “caught up.” Consequently and predictably, from time to time there is a “slug” or tidal wave of calvings. Facilities and labor, unless prepared for and anticipated, get overwhelmed. Cow and calf health and welfare often suffer.

Calving slugs can also be due to preliminary or intermittent use of sexed semen, or the purchase of replacement heifers to fill a “hole” in calvings. Avoid calving slug slip-ups by planning ahead and devoting sufficient manpower, facilities, medicine, and feed for these events.

Dairies thrive on routine and predictability. Murphy’s Law thrives on unpredictability. Minimize your dairy’s “slips between the cup and the lip” through anticipation and preparation. It will serve you well.