Why are all teats dipped with a pre- and postmilking teat disinfectant? Are pre- and postmilking teat disinfectants designed the same? Are premilking teat disinfectants designed to clean the teat like dish soap?

Let’s tackle these basic, but important questions related to teat hygiene and health.

The primary goal of premilking teat disinfectants is to disinfect the skin of the teat prior to milking. Premilking teat disinfectants reduce or kill bacteria on the teat, loosen organic matter, and aid in the prevention of mastitis caused by environmental bacteria.

Typically, premilking teat disinfectants have wetting agents in them to loosen organic matter on the teat, but they are not designed to work like dish soap. Interestingly, most products used as premilking teat disinfectants were designed as a postdip so they lack some of the cleaning potential of a product engineered as a predip.

The Pasteurized Milk Ordinance (PMO) states, “Teats shall be treated with a sanitizing solution just prior to the time of milking and shall be dry before milking.” Premilking teat disinfectants are designed to meet the rules for interstate shipment as listed in the PMO.

Keep in mind that premilking teat disinfectants do not completely eliminate all bacteria. At best, the most effective premilking teat cleaning and sanitizing can reduce bacteria counts by 85 percent.

Decades of value

The real value of predips was established from research in the 1970s and ‘80s, some of which was published by Cornell University. An example is a paper by Dave Galton and his colleagues, “Evaluation of udder prep on intramammary infections,” which was published in 1988. The discovery was that reducing bacteria on teats before milking reduced the incidence of new environmental mastitis cases.

The other important reason to disinfect teats before milking is to harvest a safe food product. Besides pasteurization, little can be done to milk at the processing plant to fix high raw bacteria levels. The largest portion of bacteria in raw milk typically comes from the teat skin. Keeping teats as clean as possible between milking has the greatest impact on the success of disinfecting the teat prior to milking.

Delivers a great deal

Postmilking teat disinfectants are designed to kill bacteria on the teat surface after milking, maintain and even improve skin condition, exfoliate skin, and control contagious bacteria that cause mastitis. The milk residue on the teat surface after milking acts as food for bacteria. The postmilking teat disinfectant helps dilute and rinse some of this milk off the teat surface. Both of these steps reduce the risk of bacteria invading the open teat end after milking.

Postmilking teat disinfectants also contain skin moisturizers that are designed to prevent drying and cracking of the teat skin. There are four different classes of skin moisturizers used in teat disinfectants:

- Occlusive

- Humectants

- Emollients

- Exfoliants

Each class of skin moisturizer functions differently, but the goal is still the same — to provide a teat surface that is free of dry or cracked skin.

Teat disinfectants can be applied with a dipper cup, wand, foamer, or even a sprayer. Applying teat disinfectants with a dipper cup, wand, or as a foam are the desired application method given the importance of covering the entire teat surface with the disinfectant.

Foaming a dip typically reduces the amount of dip used per application. Interestingly, the viscosity of the dip has a major influence on the amount of dip used per application. A thick dip drips less but you use more because more product sticks to the teat surface. Application of dip via spraying usually raises dip usage by 15 percent and teat dip coverage on the entire teat surface is typically the worst.

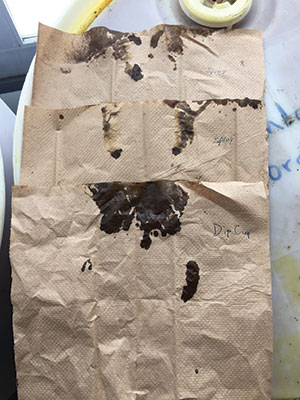

Wrapping a paper towel around the teat after teat dip application is one way to determine if the entire teat surface was covered with the disinfectant. The entire portion of the towel touching the teat should be wet from the disinfectant if the entire teat was covered with the disinfectant. Notice in the photo of the towel test after spray application, the entire surface of the teat is not covered as compared to applying the teat disinfectant with a dipper cup or wand.

The active ingredient in teat disinfectants that kills bacteria is called the germicide. There are different classes of germicides used in pre- and postmilking teat disinfectants. All germicides that come in contact with organic matter are weakened, which means there is less germicidal activity to kill the bacteria under high organic load.

There are mainly two classes of germicides used in teat disinfectants:

- Oxidative

- Nonoxidative

Oxidative germicides typically have the broadest spectrum of bacteria that are killed. Examples of oxidative germicides are iodine, chlorine dioxide, chlorine, hydrogen peroxide, and ozone. Products like hydrogen peroxide work best when little organic matter is on the teats prior to applying the teat disinfectant. Nonoxidative teat disinfectants are more targeted on the classes or types of bacteria that they kill. Examples of nonoxidative dips are chlorhexidine, fatty acids, and alpha hydroxyl acids. Nonoxidative germicides often work best when paired with an oxidative germicide.

Have you ever heard of a “barrier” teat disinfectant and wondered what it is and what is it designed for?

There is no standardized definition of a “barrier” disinfectant that is agreed upon by the industry, academia, or government officials. Barrier disinfectants usually have polyvinyl alcohol (PVA) added to them with the idea that the PVA will create a “plastic-like” barrier over the opening of the streak canal.

The plastic-like material that makes detergent “pods” is an example of PVA. The “barrier” is designed to reduce the risk of bacteria migrating through the dip after it is dry, thus preventing colonization of bacteria on the teat skin. Barriers are postmilking teat disinfectants.

Barrier dips were designed to be used during wet conditions, most notably the rainy season in the western U.S. when cows are housed outside or during extensive periods of humidity. One of the drawbacks of “barrier” dips is they take an extended period of time to dry as compared to a nonbarrier postmilking teat disinfectant. This slow drying characteristic increases the risk of organic matter sticking to the “barrier” on the teat surface, making the teat harder to clean at the next milking.

Barriers also are the most difficult type of teat disinfectant to remove from the teat skin prior to milking. Barriers, when used during specific environmental conditions (weather and bedding type), may help with udder health issues.

The importance of pre- and postmilking teat disinfectant is in reducing the bacterial load on the teat surface and prevent mastitis. There are many questions to be asked when choosing a teat disinfectant, such as application method, dip usage, class of germicide, and skin moisturizers, to name a few.

Request the data

When choosing a teat disinfectant, request research data that shows the efficacy of the product. Remember, the success of the teat disinfectant is greatly influenced by the amount of bacteria and organic matter on the teat prior to applying it; for that reason, teat cleanliness before and after milking has a huge influence on the success of your teat disinfectant.