The starch content of corn silage is a key driver of quality and impacts the opportunity to build a cost-effective ration to drive high milk production. This value reflects many factors but is overwhelmingly a result of field moisture conditions that establish the ratio of corn to fodder.

Every year, dairymen and consultants look with anticipation to see what the early lab evaluations have to say about starch content. Apart from moisture, starch is perhaps the most watched nutrient in a corn silage analysis.

As a laboratory, we receive more questions and complaints about the starch level in corn silage than for any other analysis we perform. These concerns are not biased in a particular direction, but may be for starch reported too low, for starch reported too high, and for starch being inconsistent across samples over time. I hope to put these concerns into perspective through this discussion.

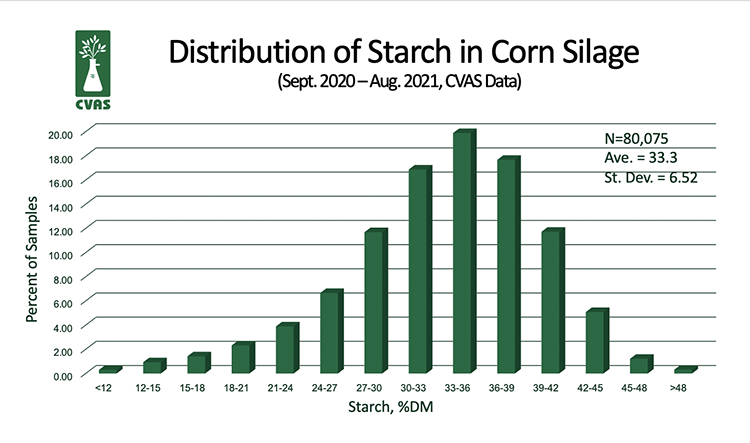

Starch as a laboratory analysis is not particularly difficult and is routinely run by all the key dairy labs in the U.S. The average starch value for tested corn silages in the U.S. by Cumberland Valley Analytical Services (CVAS) is 33.3% with a range of one standard deviation (66% of samples) falling between 26.8% and 39.8%. Laboratory data published by Dairy One shows a 33.3% average as well, with almost the same range (primarily 2019 crop year data).

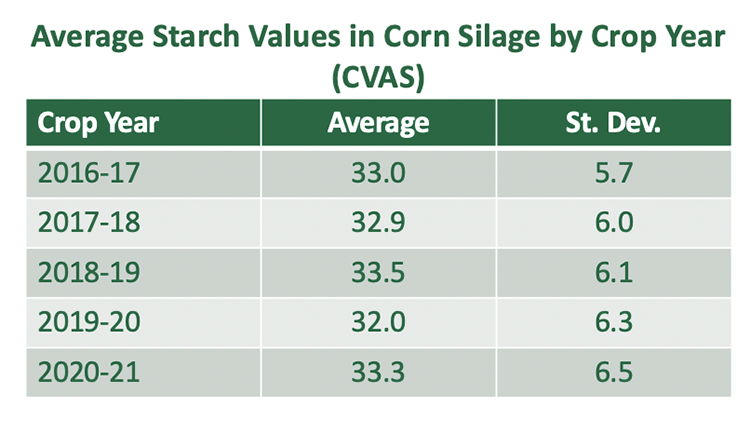

Average starch values for a lab do not change much from one crop year to another, even within region. The significant differences across crop years relate to local conditions, specific geographies, and even fields.

Kyle Taysom, director of Dairyland Labs, when asked “What does corn silage look like this year?” will respond “average and highly variable like every other year, you need to test your silage to find out what it is!” The average starch values for recent years summarized by CVAS do not change as can be seen in the table below:

Most of the analysis of corn silage starch is by near-infrared spectroscopy (NIR). Many are concerned that the NIR evaluation of starch is suspect and not necessarily accurate. Work over many years shows starch to be one of the better predicted nutrient constituents by NIR.

Our NIR calibration statistics for starch in corn silage are good (R2=0.98, SECV=0.84) and a test of the NIR model against routine samples showed good performance as well (R2=0.94, RMSE=1.32). Bottom line, NIR is generally not the “culprit” when starch values vary considerably from expectations.

Sampling a concern

The greatest challenge in obtaining lab values that reflect the corn silage being tested centers on sampling. This statement may sound like an old and worn-out response, but it is true.

Sampling of either the original material on the farm, or sub-sampling by the lab has been proven to be the greatest source of error. In a 100 gram of sample, which is often the size that is dried and ground as a test portion by the lab, adding or subtracting the equivalent of 15 kernels of corn can shift the starch value by more than 2%!

When confronted by the statement that the starch value in an analysis report is “wrong,” I generally start by asking what the reported neutral detergent fiber (NDF) is and if that seems to be wrong as well. If there is a concern about the starch value, then there is generally agreement that the NDF appears to be off in the opposite direction.

This takes us back to the root problem of sampling and the relationship of grain to fodder in the sample taken. As there is a complementary relationship between nutrients in a typical corn silage sample, you can estimate starch as a relationship to other nutrients.

The following equation allows you to “check” your starch against other nutrients within a range of +/- 2.5 units: Starch = 89.4 - 1.48(CP) - 1.03(aNDF) - 0.678(ash); (CVAS, 2016).

Multiple samples a must

When using lab analysis to characterize corn silage, do not rely on any one sample. Test regularly and allow the “working” starch value to be an average from several samples. If a starch value appears incorrect or is not consistent with what has been reported from earlier samples, take another to confirm if there has been a true change.

Having the lab “recheck” a starch is not always the best approach. If there is a sampling problem, the lab will tend to report back the same value as the material being tested is the same.

When pulling a sample at the farm, work to fill the sample bag with the most representative sample possible. This limits the opportunity for sampling error at the lab. Do not send more material than is necessary for the test being performed. The more that the lab must work to subsample from a large amount of material, the greater the opportunity for error.

The starch content of corn silage significantly defines its value. Having an accurate understanding of starch supports critical ration development and drives economic decisions. Invest in proper sampling, sample frequently to understand true variation, and communicate with your lab service provider if there are concerns about analysis results.