The author is owner of Cumberland Valley Analytical Services, Hagerstown, Md.

Soybean meal is one of those basic ration ingredients that we can take for granted. It is among the most essential of commodities fed to dairy cows and accounts for two-thirds of the world’s high-protein animal feed.

Since soybean meal is purchased and fed for its protein content, it should be evaluated based on the cost per unit of protein fed. Both moisture and protein play a big role in determining that as-fed protein level.

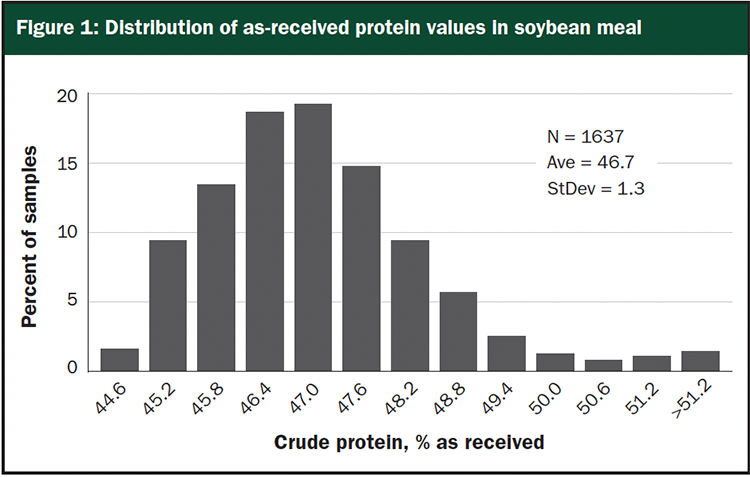

The feed marketplace typically refers to soybean meal as 48% protein. In futures contracts, it is traded based on being greater than 47.5% protein and less than 13% moisture. Many nutritional guidelines and reference values in nutritional programs assume that soybean meal will be 48% protein as-received (around 54% on a dry matter basis). However, that is not the reality of what is typically fed. Years ago, soybean meal may have more routinely met the expectation of 48% protein.

A review of over 1,600 soybean meal (SBM) samples that ran for chemistry protein at Cumberland Valley Analytical Services (CVAS) over the last four crop years reveals that many SBM samples provide less than the book value of 48% protein. The average value is 46.7%, with a one standard deviation range of 45.4% to 48% as shown in the figure.

There are relatively few soybean meal samples testing over 48%. However, the average is pulled down by samples of heat treated or specialty soybean meal samples that are included due to inability to recognize and exclude those samples from the data summary shown in the figure.

When purchasing soybean meal, it is important to understand the protein and moisture definition of what is being purchased. It is acceptable for a protein valuation to be lower than 48% if buyer and seller understand the expected level and accept a reasonable level of variation.

In our laboratory, we would expect to be able to define the as-received protein value of soybean meal at plus or minus 0.3%. At CVAS, many samples of soybean meal are evaluated routinely by feed manufacturers to understand quality and to be able to correctly formulate around differences. When there is a

dispute regarding large contracts, suppliers will often require that samples be tested by “NOPA” labs certified by the National Oil Processors Association.

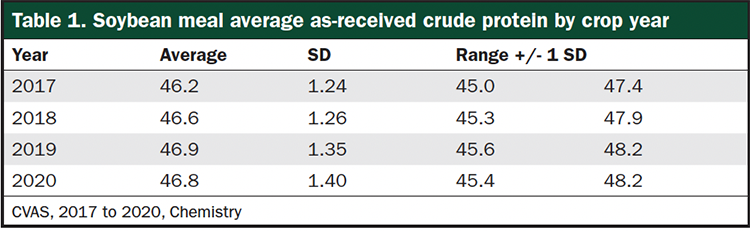

An evaluation by crop year shown in Table 1 shows that there is not much variation in soybean meal from season to season. Variation may be more likely within given geographies and through different crushing plants.

These days, there is a significant opportunity with a wide range of treated soy products that protect protein, and thus amino acids, from rumen degradation and deliver them to the intestinal tract for absorption. These products were not generally available just a generation ago and can bring significant value beyond what is provided from traditional soybean meal.

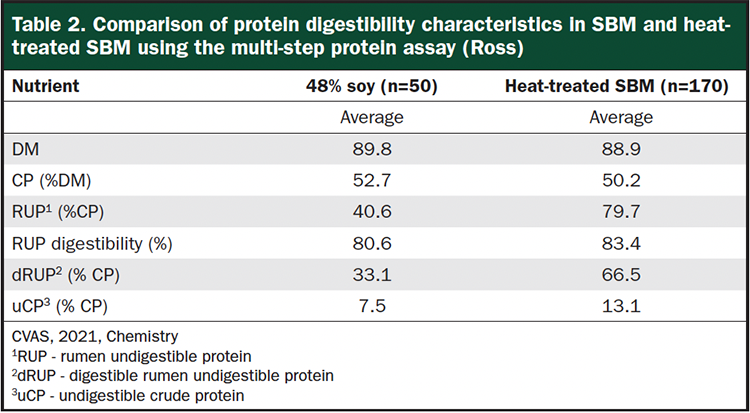

We now have laboratory assays that allow us to evaluate and rank the digestibility characteristics of treated soy products and other rumen bypass protein sources. In situ, in vitro, and the Ross assay allow for labs to characterize protein degradability with varying cost, accuracy, and precision. Table 2 depicts a summary of soybean meal samples and heat-treated soybean meal samples compared using the multi-stop protein assay of Ross (MSPE).

One can observe a significant improvement in the rumen undegradability of heat-treated soy compared to traditional soybean meal as shown in Table 2. While the heat-treated material allowed for ruminal bypass of protein and higher levels of intestinally digestible protein (66.5% versus 33.1%), it did not on average create significant total tract undigestible protein (13.1% versus 7.5% in untreated soy).

Recognize that there is variation in the protein level of soy products sold into the market. If you are purchasing soybean meal as an ingredient, evaluate samples for moisture and protein routinely. It is not costly and allows you to understand and control variation.

If you are balancing rations, make sure that standard values for nutrients in software reflect the reality of what is being fed in the market. Work with your nutritionist to consider the nutritional and economic justification of treated soy products and other bypass materials. These materials, not available to past generations of dairymen, provide an opportunity for cows to express their genetic milk and component potential.