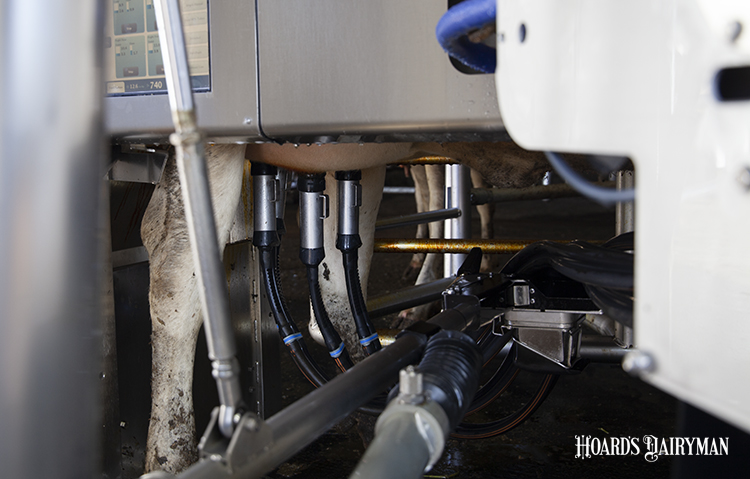

Automatic milking systems (AMS) have taken off for the same reason many technologies do — they save labor. A repetitive task like milking is a good job for robots, and they can be consistent and skilled while requiring no training or days off. However, they still need to have the proper care and be in the right environment for the entire system to function efficiently.

Marcia Endres at the University of Minnesota has studied what factors influence production efficiency in AMS herds, and she shared four keys to success during a presentation at the Dairy Cattle Reproduction Council Annual Meeting.

Cow management and health: Since cows are taking themselves to be milked, they must be able to move well. Endres pointed to data that found that locomotion scores of at least a 3 were associated with 0.3 fewer milkings per cow per day. That can add up quickly in lost milk and time spent fetching lame cows.

Whether it’s due to lameness or other reasons, variation in the milking interval was also negatively associated with production, she continued. To ease the transition for heifers, she noted that training them through the box before calving has been shown to be helpful. When this isn’t practical, farmers may use a box-type environment to provide feed in the dry pen.

AMS can provide a lot of data, often including things like health monitors. These allow individual observations within the group. In a Canadian study, 80% of producers said their technology made it easier to identify disease in their herd. Making your system easy to work with is critical to capitalize on these advantages, Endres advised.

Feeding management: With no set daily routine, the feed provided must be palatable so cows want to get up and eat. Then, they often go to get milked as well. “Access to feed really makes milk,” the professor of animal science said.

Quality forages do no good if cows can’t get to them, so be sure to keep feed pushed up. She described a study where farms that utilized automatic feed pushups realized almost 11 more pounds of milk per cow.

Endres also noted that in many AMS, four different types of pellets can be delivered, though farms often stick to just one. This customizable diet can encourage cows to get milked.

Barn management: Heat abatement and ventilation are still key in a robot barn, and Endres shared that her group sees many cross-ventilated robot barns. Overall, ensuring the barn keeps cows comfortable and encourages an easy flow to the AMS will enhance efficiency.

Sand bedding also works well, and even waterbeds can be successful. Keeping cows and teats clean is key since there will be no human inspection of the udder when the animal gets milked. “Bringing this cow clean into the robot makes a difference,” Endres stated. “If a cow comes in too dirty, it’s hard to clean all of that.”

Equipment maintenance: Finally, she stressed that keeping up with the needs of the machine is critical to reduce wasteful downtime that can quickly snowball its effects on the herd. When a member of the farm team can perform regular maintenance, costs are saved, but she still recommended having a dealer located within a few hours of the farm so that expertise is available.

A whole-system approach that covers each of these areas will help a farm get the most efficiency out of the investment they make in AMS, Endres emphasized.