The author is a professor emeritus of animal sciences at the University of Illinois, Urbana.

As shelled corn prices are a couple dollars higher per bushel (56 pounds as-fed basis) compared to prior years, dairy farmers are asking what alternatives and strategies could be considered to reduce feed costs without sacrificing milk yields or components. The situation appears to be with us for a while due to higher fertilizer and chemical costs in 2022.

That, in turn, indicates growing corn silage and grain also will be a higher cost proposition. USDA estimated shelled corn prices at $4.80 bushel in 2022, but this will change depending on growing conditions, acreage (soybean are cheaper to raise), exports to China and other countries, and growing conditions in both Brazil and Argentina.

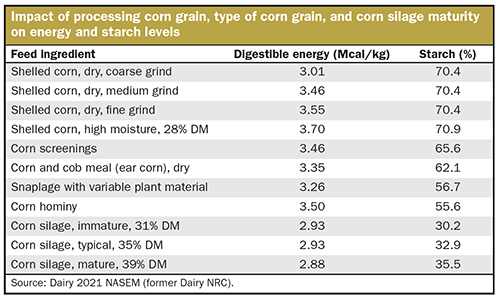

Shelled corn can contain over 70% starch (see table). Starch drives dry matter intake, elevates microbial growth, captures rumen degraded protein, and enhances milk yield when levels are optimal. If starch is excessive, rumen acidosis and reduced fiber digestion can occur. Several considerations are listed below.

More corn silage

Corn silage can vary from 28% to 38% starch and be over 60% neutral detergent fiber digestibility (NDFD). It is an excellent source of energy for rumen bacteria from both a fiber and starch standpoint and thus an excellent energy source for cows. When evaluating the economic value of corn silage using Sesame software (from The Ohio State University), it has one of the best feed nutrient values — current prices for corn silage are below break-even.

A high corn silage forage-based ration can provide most of the starch needed. One ton of corn silage may contain 7 to 8 bushels of corn grain, which can be 390 to 460 pounds in 700 pounds of total yield (on an as-fed basis) or 60% of the corn silage dry matter. If you feed 25 pounds of corn silage dry matter, your cows may be consuming 15 pounds of corn dry matter. Also, if inventory allows, starch availability improves due to fermentation during three to six months in storage, allowing for greater starch utilization in the digestive tract.

Take-home message: All corn hybrids are not created equal. Carefully decide when purchasing your corn silage seed corn. Consider maturity time (days), because as corn silage matures, it increases in dry matter and starch content (see table). Given that situation, select hybrids higher in NDFD. This includes lower-lignin corn silage, hybrids with an amylase enzyme in the corn grain, higher oil content, and/or soft endosperm starch. Yield is always important based on independent test plot data.

Processing corn grain

One guideline is to have 70% of the starch fermented in the rumen to drive volatile fatty acid (VFA) production as an energy source, optimize microbial growth, and capture rumen ammonia as microbial amino acids (protein). The table illustrates that the energy content of corn grain can change depending on processing.

The energy unit in the 2021 Dairy NASEM (former Dairy NRC) is digestible energy, which is used in the rumen model. Grinding corn to a smaller particle size exposes the starch to digestive enzymes and bacteria improves fermentation due to a greater surface area. Likewise, high-moisture corn breaks down the protein (prolamine) encasing of the starch granules. Meanwhile, steam flaking solubilizes (cooks) the starch.

Optimal processing must be achieved (see table). Grinding dry corn can range from a 400 to 900 average micron size. Growing conditions can impact the kernel hardness, requiring more processing with dry corn. In the 2021 growing season, late-summer moisture resulted in higher starch filling with harder kernels, requiring more processing (such as processing from 600 down to 400 micron size).

With high-moisture corn, optimal moisture can influence storage and cow performance. Suggested levels of corn moisture are:

• High-moisture shelled corn: 28% to 30%

• High-moisture ear corn: 30% to 34%

• Snaplage: 55% to 60%

With steam-flaked corn, target 24- to 26-pound bushel weight (the corn kernel is flattened and translucent).

Processing corn silage

With the ability to kernel process corn silage (also called plant processing), dairy farmers can ensure starch in corn silage is available to the rumen bacteria and dairy cows’ digestive enzymes. As the crop matures (over 32% dry matter), the kernel becomes harder and must be crushed. Immature corn silage (under 30% dry matter) may not require kernel processing, but it will be lower in starch content (as shown in the table).

Take-home message: Inspect your current corn silage and evaluate the degree of kernel processing. No corn kernels should be observed in the silage. If kernels are present, you may see the kernels again in the manure. Kernel processors should be tightened down to 1 to 2 millimeters depending on the stage of maturity and kernel hardness. Conduct a kernel processing score of your current corn silage inventory through forage testing labs. Target a score of over 70%, reflecting proper kernel processing.

Consider by-product feeds

Hominy can be one alternative by-product feed with variable levels of starch and fat, as shown in the table. Check with the plant producing hominy feed to determine nutrient levels. The Sesame computer program indicates corn hominy can be a better buy than shelled corn, but some starch has been removed, so adjust rations. Molasses, citrus pulp, beet pulp, and almond hulls contain sugar, which is another carbohydrate fermented in the rumen.

Check costs per unit of energy when considering these starch alternatives. Several of these by-product feeds can be high in NDFD and provide another energy source, which may result in acetic or butyric acid production (both volatile fatty acids or VFA). Propionate from starch fermentation is a precursor of blood glucose needed for milk lactate production in the udder, a strong immune system, and ovarian function.

Take-home message: Recommended ration total — sugar levels range from 6% to 8%, if economical. Sugar can replace starch in the ration.

Fecal starch analysis

Checking fecal starch levels allows the dairy farmer or nutritionist to determine if dietary starch is being utilized. Send a mixed manure sample from several cows to a commercial lab to be tested for starch. If the value is high, determine the source of starch escaping digestion. It could be corn silage, corn grain, barley grain, small grain silage, or other starch sources in the diet.

Take-home message: Fecal starch levels should be under 3%. Values between 3% to 5% require analysis to determine the source. If your current corn silage was not processed properly, nothing can be corrected, requiring more $7 per bushel corn. If it is from a grain source such as corn or barley, more processing should be considered. For every one-unit change in fecal starch, an increase or decrease of 0.6 pound of milk can occur.