As new technologies emerge, milking cows robotically continues to gain interest and adoption, but there’s a gap between research and farm level application. Most land grant universities do not manage robotic milking systems, so controlled research on intensive management of robotic dairy systems is somewhat limited.

Many questions arise when managing a robotic dairy system, especially during periods of low milk prices. Here’s a few we’ve heard:

What truly influences milk production on a robotic dairy? What influences milk income over feed cost? Do pellet characteristics influence visits and milk production? Does the energy density of the PMR (partially mixed ration) affect milk production?

To address some of these questions, the team at Vita Plus Loyal conducted a survey of 32 Upper Midwest dairies during the summer of 2018.

Survey herds’ milk production ranged from 60 to 97 pounds per cow per day. Robot visits (milkings per day) ranged from 2.4 to 3.1 visits per cow per day, and milk production per visit ranged from 21.4 to 39 pounds per visit. We also conducted a detailed robot pellet and PMR cost and composition analysis. Cost of robot pellets ranged from $132 to $500 per ton. The cost of the PMR on a dry matter basis was less variable at $130 to $190 per ton.

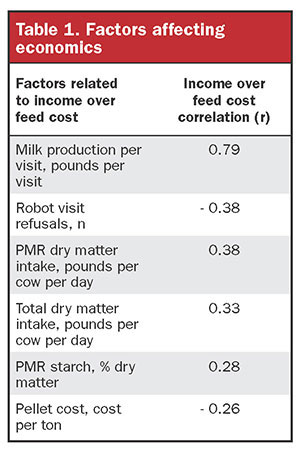

Income over feed cost was a key metric evaluated in this survey. The primary factors associated with income over feed cost on robotic dairies are presented in Table 1. Most surprising, the average visits to the robot had no effect on income over feed cost. Rather, and somewhat logically, milk production per visit had the greatest positive influence.

In contrast, robot visit refusals and cost of the robot pellet or supplement had a negative effect on income over feed cost — a key finding of this survey. Robotic dairies with the highest income over feed cost often fed very low-cost robot pellets, such as corn gluten feed and/or simple combinations of shelled corn and soybean meal. Further, robotic dairies with higher income over feed costs fed less total pounds of feed through the robot. These data are in direct contrast to the more common dogma that the robot pellet has a major influence on milk production and profits in a robotic milking system.

A non-nutritional item that had a major effect on income over feed cost was the use of sand bedding. Herds using sand bedding were compared to herds using alternative bedding sources. Use of sand bedding had no effect on the number of visits, but it significantly improved milk production per visit by 3 pounds. With an average of 2.7 visits per cow per day, sand bedding raised daily milk production by 8.1 pounds per cow and significantly increased milk income over feed cost.

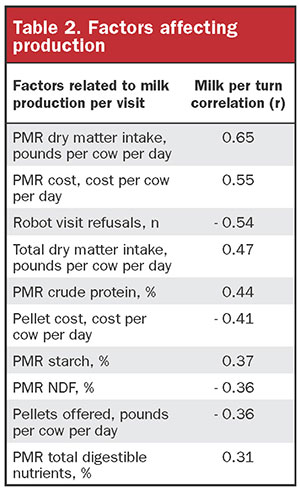

Because milk production per visit had the most significant influence on income over feed cost in our survey herds, we also evaluated factors that influence milk production per visit.

Interestingly, the cost of the PMR had a positive correlation to milk production per visit in our survey herds. Robot dairies that fed their cows higher-cost PMRs had greater milk production per visit. This is further supported by the observation that herds feeding PMRs balanced for higher crude protein and lower NDF (neutral detergent fiber) had higher milk production per visit.

In contrast, cost of the robot pellet and the amount of pellets offered at the robot had a negative effect on milk production per visit. The data from our survey herds suggest nutritional emphasis on feeding more nutrient-dense PMRs and less nutritional reliance on robot pellet or supplement improved milk production per visit.

In the robotic dairies we surveyed, milk production per visit was highly variable, but that ultimately was the driving factor influencing income over feed cost. The simple metric of visits per day was not very informative regarding milk production or income over feed cost.

Keep pellets simple

The biggest surprise from our survey was the lack of influence the robot pellet played on milk production and how the use of a low-cost, simple robot pellet helped improve the bottom line. In fact, the cost of the robot pellet or supplement had a negative effect on income over feed cost and milk production per visit. We could not find where the nutritional composition or flavoring of the robot pellet had any effect on visits or production per milking.

Robot herds feeding more nutrient-dense PMRs and where cows were bedded with sand had greater milk production per visit, which appeared to raise income over feed cost. Results from this survey suggest many dairies with robotic milking systems are successfully feeding low-cost robot pellets and, by doing so, are bolstering their bottom lines.