The authors are with the School of Veterinary Medicine, University of Wisconsin-Madison.

Both natural ventilation and negative pressure systems have wintertime limitations in calf barns. When designed and installed correctly, positive pressure tubes can alleviate problems.

In the eight years since we designed our first positive pressure tube ventilation system for a calf barn, interest has grown. Today, hundreds are being installed each month. What explains the dramatic adoption of the system, and what do these new systems offer that traditional models do not?

While positive pressure tube systems have existed in livestock buildings for about 50 years, the new systems are different. The traditional tube was powered by a fan located about 3 feet inside the barn wall and away from a wall louver. The interior fan location made them primarily recirculation systems. While they helped to equalize temperature throughout a barn, they also distributed dust and bacteria through the space.

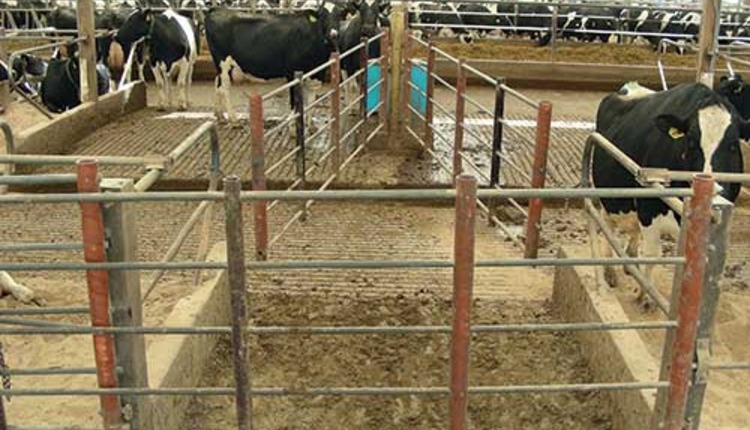

If any single animal released respiratory pathogens into the air, the traditional recirculation tube ensured that every other animal in the barn was fully exposed to the germs. In contrast, the new positive pressure tube ventilation systems are powered by fans mounted in the outer walls. They deliver 100 percent fresh, and sometimes cold, air into a self-contained tube with custom-sized holes that distribute the air in a controlled pattern throughout the barn. With modern design techniques, fresh air can be delivered into the microenvironment of every calf without producing a draft.

Calf barns are usually designed so that the barn can be ventilated at low rates in cold weather and higher rates in warm weather. It is helpful to think of the minimal ventilation rates as sufficient to support respiratory health, while higher rates are used to prevent heat accumulation. While natural ventilation and negative pressure systems can ventilate calf barns efficiently in warm weather, both of those approaches have inherent problems in winter. It is the ability of positive pressure tube systems to deliver the minimal ventilation rates without a draft to every calf that is the driving force behind their adoption.

Naturally ventilated buildings are designed to use two forces for ventilation: wind moving against and over the building and thermal buoyancy of warmed air rising to exit through a ridge opening. Because natural ventilation occurs without the added costs of fans or electricity, it should be utilized as fully as possible.

Natural ventilation has limitations

However, natural ventilation has a number of shortcomings. First, the wind sometimes stops. When the wind stops, adult cows generate sufficient heat for thermal buoyancy to successfully ventilate the barn. However, a calf barn is in trouble on a still day because the calves generate little heat. Ventilation due to thermal buoyancy is dependent upon the outside temperature being colder than the air inside the barn. Toward midday, it is often warmer outside as shown in the graph.

But even if there is wind during these conditions, warmer outside air will tend to rise rather than fall into the calf area after it enters the barn. During those hours when the outside temperature is higher, natural ventilation will perform poorly in both windy and still conditions. Finally, air moving by wind enters a barn predominantly on the windward side, and distribution of that fresh air across the entire barn is unlikely in winter when the overall air exchange rate is quite low.

Negative pressure has shortfalls, too

The traditional negative pressure system, an exhaust fan on a wall and air inlets around the building, also has significant limitations. A good negative pressure system depends upon an appropriately sized exhaust fan. The fan must be matched with inlets sized so that incoming air mixes well with the interior air and located so that the incoming air is well distributed. Yet, in our analysis of hundreds of calf barns, these conditions are rarely achieved.

It is generally recommended that the winter exhaust rate should provide for four theoretical air changes per hour, but fans are often sized inappropriately. Negative pressure systems also require that the total air inlet area is matched to fan size. To achieve air mixing, inlets are usually sized so that air enters the barn at about 500 feet per minute, which translates into 2 square feet of inlet per 1,000 cubic feet per minute of fan capacity.

With the low ventilation rates used in winter, it is extremely difficult to construct the very small inlets that are required and it is even more difficult to keep them from becoming plugged with dust or debris. The situation is further complicated in that any other unplanned inlets into the barn will disrupt the planned distribution of incoming air. For perspective, it is common for 20-year-old homes to have more than 2 square feet of unrecognized "inlets." Most calf barns are far less "tight" and have more areas of unplanned openings than houses. While negative pressure systems are a practical solution for many large volume ventilation needs, they are particularly problematic in situations with low rates of air exchange.

Positive pressure offers a solution

A positive pressure tube ventilation system offers three main benefits: consistency of performance, uniform distribution of fresh air, and compatibility with most natural and negative pressure barns in winter. Since the fan and perforated tube are a self-contained unit, conditions such as still winds or unrecognized crevices in building walls are not problems.

Because the systems do not recirculate air, it is rare for particles to accumulate in the tube and plug the system. They offer remarkable consistency over time. With proper design, the air discharge from the tube can be uniform from end to end. By locating the discharge tube within the barn, small volumes of air can be delivered to interior locations that are either impossible or extremely expensive to reach with negative pressure wall inlets.

With these attributes, positive pressure tube ventilation systems can correct most of the seasonal limitations seen with natural and negative-pressure ventilation in calf barns. They are compatible with naturally ventilated calf barns because the air introduced through the tube can ventilate the barn and then leave without restrictions through open ridges and space above sidewall curtains. The tube systems can be used to achieve the winter exchange rates in negative pressure mechanically ventilated barns provided that there is sufficient "inlet" area to allow the air to leave the barn without restriction.

The general approach is to provide the minimal winter ventilation rate through the tube system and use either natural or negative-pressure mechanical systems as the predominant method as the weather moderates. Because of these benefits, positive pressure tube ventilation systems are becoming a popular solution to many of the respiratory disease problems in our traditional barns.

Click here to return to the Calf & Heifer E-Sources

130325_195

In the eight years since we designed our first positive pressure tube ventilation system for a calf barn, interest has grown. Today, hundreds are being installed each month. What explains the dramatic adoption of the system, and what do these new systems offer that traditional models do not?

While positive pressure tube systems have existed in livestock buildings for about 50 years, the new systems are different. The traditional tube was powered by a fan located about 3 feet inside the barn wall and away from a wall louver. The interior fan location made them primarily recirculation systems. While they helped to equalize temperature throughout a barn, they also distributed dust and bacteria through the space.

If any single animal released respiratory pathogens into the air, the traditional recirculation tube ensured that every other animal in the barn was fully exposed to the germs. In contrast, the new positive pressure tube ventilation systems are powered by fans mounted in the outer walls. They deliver 100 percent fresh, and sometimes cold, air into a self-contained tube with custom-sized holes that distribute the air in a controlled pattern throughout the barn. With modern design techniques, fresh air can be delivered into the microenvironment of every calf without producing a draft.

Calf barns are usually designed so that the barn can be ventilated at low rates in cold weather and higher rates in warm weather. It is helpful to think of the minimal ventilation rates as sufficient to support respiratory health, while higher rates are used to prevent heat accumulation. While natural ventilation and negative pressure systems can ventilate calf barns efficiently in warm weather, both of those approaches have inherent problems in winter. It is the ability of positive pressure tube systems to deliver the minimal ventilation rates without a draft to every calf that is the driving force behind their adoption.

Naturally ventilated buildings are designed to use two forces for ventilation: wind moving against and over the building and thermal buoyancy of warmed air rising to exit through a ridge opening. Because natural ventilation occurs without the added costs of fans or electricity, it should be utilized as fully as possible.

Natural ventilation has limitations

However, natural ventilation has a number of shortcomings. First, the wind sometimes stops. When the wind stops, adult cows generate sufficient heat for thermal buoyancy to successfully ventilate the barn. However, a calf barn is in trouble on a still day because the calves generate little heat. Ventilation due to thermal buoyancy is dependent upon the outside temperature being colder than the air inside the barn. Toward midday, it is often warmer outside as shown in the graph.

But even if there is wind during these conditions, warmer outside air will tend to rise rather than fall into the calf area after it enters the barn. During those hours when the outside temperature is higher, natural ventilation will perform poorly in both windy and still conditions. Finally, air moving by wind enters a barn predominantly on the windward side, and distribution of that fresh air across the entire barn is unlikely in winter when the overall air exchange rate is quite low.

Negative pressure has shortfalls, too

The traditional negative pressure system, an exhaust fan on a wall and air inlets around the building, also has significant limitations. A good negative pressure system depends upon an appropriately sized exhaust fan. The fan must be matched with inlets sized so that incoming air mixes well with the interior air and located so that the incoming air is well distributed. Yet, in our analysis of hundreds of calf barns, these conditions are rarely achieved.

It is generally recommended that the winter exhaust rate should provide for four theoretical air changes per hour, but fans are often sized inappropriately. Negative pressure systems also require that the total air inlet area is matched to fan size. To achieve air mixing, inlets are usually sized so that air enters the barn at about 500 feet per minute, which translates into 2 square feet of inlet per 1,000 cubic feet per minute of fan capacity.

With the low ventilation rates used in winter, it is extremely difficult to construct the very small inlets that are required and it is even more difficult to keep them from becoming plugged with dust or debris. The situation is further complicated in that any other unplanned inlets into the barn will disrupt the planned distribution of incoming air. For perspective, it is common for 20-year-old homes to have more than 2 square feet of unrecognized "inlets." Most calf barns are far less "tight" and have more areas of unplanned openings than houses. While negative pressure systems are a practical solution for many large volume ventilation needs, they are particularly problematic in situations with low rates of air exchange.

Positive pressure offers a solution

A positive pressure tube ventilation system offers three main benefits: consistency of performance, uniform distribution of fresh air, and compatibility with most natural and negative pressure barns in winter. Since the fan and perforated tube are a self-contained unit, conditions such as still winds or unrecognized crevices in building walls are not problems.

Because the systems do not recirculate air, it is rare for particles to accumulate in the tube and plug the system. They offer remarkable consistency over time. With proper design, the air discharge from the tube can be uniform from end to end. By locating the discharge tube within the barn, small volumes of air can be delivered to interior locations that are either impossible or extremely expensive to reach with negative pressure wall inlets.

With these attributes, positive pressure tube ventilation systems can correct most of the seasonal limitations seen with natural and negative-pressure ventilation in calf barns. They are compatible with naturally ventilated calf barns because the air introduced through the tube can ventilate the barn and then leave without restrictions through open ridges and space above sidewall curtains. The tube systems can be used to achieve the winter exchange rates in negative pressure mechanically ventilated barns provided that there is sufficient "inlet" area to allow the air to leave the barn without restriction.

The general approach is to provide the minimal winter ventilation rate through the tube system and use either natural or negative-pressure mechanical systems as the predominant method as the weather moderates. Because of these benefits, positive pressure tube ventilation systems are becoming a popular solution to many of the respiratory disease problems in our traditional barns.

130325_195