The author is a professor emeritus of animal sciences at the University of Illinois, Urbana.

Dairy farmers are facing higher corn and soybean meal prices in 2021. Corn has moved from $3 a bushel to over $6 a bushel while soybean meal is up $100 a ton. Reasons for these sharp price hikes include lower yields in 2020 due drought conditions late in the growth period, expanded export to China and other countries, a compromised Brazilian crop, and rebooting of ethanol plants.

Corn (a source of energy and starch) and soybean meal (a source of protein) “pull” or elevate other feed ingredients, including by-product feeds, to higher prices as well. One theory is higher feed prices lead to higher milk prices. Other questions relate to future grain prices, alternatives to these price forages, and strategies on your farm.

One item has not changed: cows still need amino acids, glucose, and fatty acids to produce milk yield and components. Cows do not change their nutrient requirements as feed prices climb.

Future grain prices

Dairy farmers and nutritionists are asking if these prices will decline in 2021. In February, USDA estimated that corn acreage would climb 1.3% to 92 million acres with a projected price of $4.20 a bushel. Target corn yields were listed at 179 bushels per acre.

Soybean acreage was expected to increase 8.3% to 90 million acres with a target price of $11.25 a bushel and 50 bushels per acre. One important factor will be the acres that are actually planted. Agricultural economists indicate more profit potential with soybeans compared to corn. Crop rotation factors impact this decision, too.

A second factor will be the growing season (moisture, planting dates, and growing degree days). Large areas of low soil moisture and drought exist in the western Corn Belt and southwest areas of the U.S. Lower numbers of prevent plant acres are expected in 2021.

Corn grain strategies

Corn grain is a primary source of energy in the ration. In Canada and Western Europe, barley and wheat can replace corn grain if economical. Renewed interest in sorghum grain is occurring as the crop requires less moisture and is more drought tolerant.

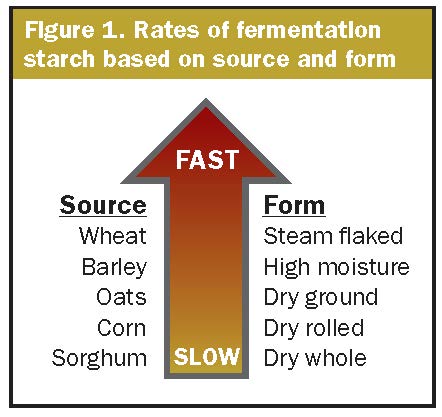

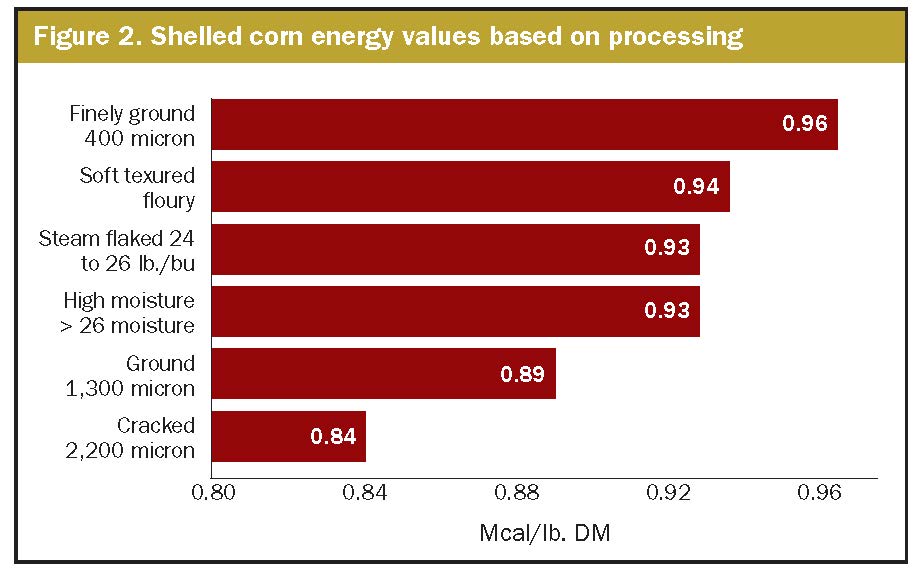

All starch is not equal. Corn grain has a slower rate of fermentation in the rumen depending on processing and particle size (Figure 1). The energy content of corn is changed based on its processing (Figure 2).

Starch must be physically available to be fermented and/or digested in the small intestine. Targeting 65% to 70% of ration starch can be fermented by rumen microbes, leading to high levels of volatile fatty acids (VFA) providing 80% of required energy and 65% of high quality amino acids. Starch ferments to higher levels of propionic acid, which can be converted by the liver to blood glucose.

Propionic acid also has the highest energy efficiency compared to other rumen VFA (no methane losses). The bad news is excessive starch can lead to rumen acidosis and digestive disorders.

Four potential alternatives

Alternative 1. Forage quality and type can be a solution. If forage quality is higher in neutral detergent fiber digestibility (NDFD), it can stretch the corn inventory. Corn silage continues to be a “super star,” providing over 45% of starch needs (over 20 pounds of dry matter per day). Legume, grass, and small grain forages can be over 50% to 60% NDFD and provide a source of rumen degradable protein (nitrogen) that must be captured by rumen microbes when rumen degradable protein (RDP) levels are balanced with fermentable carbohydrates.

Alternative 2. Substituting by-product feeds for corn can lower corn needs and ration costs. Conduct a cost comparison using a software program such as SESAME from The Ohio State University. Corn gluten feed and wheat midds are priced below break-even prices (good buys), while soy hulls and beet pulp are more expensive. Check the total neutral detergent fiber (NDF) levels in the ration to assess the impact on rumen fermentation, dry matter intake, and rate of feed passage in the digestive tract.

Alternative 3. Consider shifting the level of rumen fermentable carbohydrates (RFC) as sources of microbial energy. RFC includes starch (variable fermentation rate), sugar (fast rate), and soluble fiber (slower rate yielding less propionic acid). For high-producing cows, target a total ration level of 38% to 40% (on a 100% dry matter basis). Using RFC allows you to mix and match various feed ingredients based on price and ration levels while maintaining performance.

Alternative 4. Be sure you are getting utilization of the current ration starch in your ration. The appearance of corn grain in feces reflects lost starch. Starch in corn silage can be more fermentable after three to four months of storage, allowing more rumen available starch. Reconstitute dry corn to 35% to 40% moisture.

Starch does not have a requirement listed in NRC 2001. But starch is needed as a source of glucose either from propionic acid production (VFA produced in the rumen) or digestion in the small intestine. Glucose is needed for milk lactose synthesis (controlling milk volume), immune system energy source, and ovarian function. Cows need a minimal level of starch. My suggestion is 21% to 23% of the ration dry matter with RFC at 40%.

Protein strategies

Dairy cows have amino acid requirements. Cows can derive 65% or more of their amino acid needs from rumen microbial synthesis, 35% from rumen undegraded protein (RUP), and rumen-protected amino acids. Using a rumen modeling program, the pounds of metabolizable protein (MP) can be calculated based on:

• Dry matter intake

• Feed ingredients selected

• Rate of feed passage

• Level of RDP and RUP

• Carbohydrate balance

These programs can also calculate the grams of amino acids provided by the MP.

Four protein options

Alternative 1. Determine if your ration is meeting MP requirements. If excessive RDP or RUP occur, remove the excess level of either source.

Alternative 2. Raw urea or slow-release urea in the rumen can be added if RDP levels are low. Typical levels of added urea are 0.10 to 0.25 pound per cow per day (45 to 110 grams). Rumen bacteria must capture this source of nitrogen as amino acids.

Excessive ammonia in the rumen is absorbed across the rumen wall and converted to blood urea nitrogen. Your rumen model will determine the optimal level of urea to add reflected as MP.

Alternative 3. If MP is low and RDP requirements are optimal, adding a feed RUP source is recommended. Select the source based on the amino acid profile of the RUP feed.

For example, heat-processed soybean meal and blood meal can provide lysine. Corn distillers grains and corn gluten meal can provide methionine. Explore other alternative sources based on computer software programs that calculate break-even prices in your area. Canola meal, cottonseed meal, corn distillers grains, and sunflower meal can be economical choices.

Alternative 4. Rumen-protected amino acids can be effective and economical to balance shortages of methionine and lysine. While these products can cost 2 cents per gram of metabolizable amino acid, milk production and component responses can be economical if strategically selected.

On-farm tools to consider

Feed efficiency allows you to compare pounds of fat-corrected milk yield to actual pounds of dry matter consumed. Depending on milk yield, a value of 1.5 to 1.65 pounds of 3.5% milk per 1 pound of dry matter.

Milk urea nitrogen (MUN) can evaluate the relationships of total protein, level of RDP, and carbohydrate balance in the rumen. Optimal MUN levels of 8 to 12 mg/dL can save nitrogen costs and improve the environment.

Kernel processing score offered by commercial labs can indicate if you crushed the corn kernel grain adequately to obtain starch utilization. Optimal kernel processing scores should be over 70%. No corn kernels should be seen when processed correctly. This score will be important in corn silage harvested over 33% dry matter.

Harvest corn silage when the corn plant approaches optimal maturity. A Midwest guideline is to expect a 1% gain in corn silage starch for each 1% increase in dry matter. For example, 30% dry matter corn silage may contain 30% starch while 36% dry matter corn silage can contain 36% starch. You need to consider optimal dry matter needed for fermentation and packing versus starch yield per acre.

Conduct a fecal starch analysis to determine if your cows are extracting optimal levels of dietary starch from their diets. Target fecal starch levels under 4%. If your herd values are higher, you are losing milk or need to feed more expensive corn to compensate for the lost starch.

Conduct a seven-hour starch degradation rate offered by commercial testing labs on your corn silage and high moisture corn to balance the amount of starch available in rumen. High values could lead to subacute acidosis (SARA); lower values may slow the rate of rumen microbial growth.