The author is a dairy specialist with Pioneer Hi-Bred International and based in Beaver Dam, Wis.

A dozen years ago I was involved with a field study in eastern Wisconsin with a local feed supplier and extension dairy specialist. Nearly 200 samples of corn and hay silage from a range of storage structures were taken and analyzed for fermentation profiles. Among the findings of that study: a minority of bunker silo samples met the density guidelines of 15 pounds per cubic foot (PCF) on a dry matter basis.

Fast forward to the last eight months - have we made much progress? Based on my bunker density measurements on several dozen farms in Wisconsin, unfortunately, not so much. Only a handful of corn silage bunkers exceeded the 15 PCF threshold; a slightly higher percentage of hay silage bunkers met that target.

How can this happen? The density targets are not new, and strategies for effective bunker silo filling are well-known. Most of these dairies were very well managed, and many of the owners/managers were surprised with the lower-than-expected density results, commenting they had more or bigger tractors packing than they "used to." It is my opinion that the two most common failures are tractor packing weight and packing depth of silage layers.

The 800 rule . . .

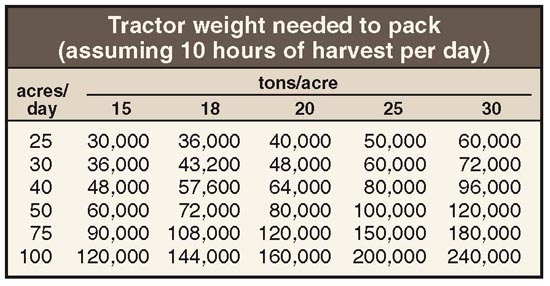

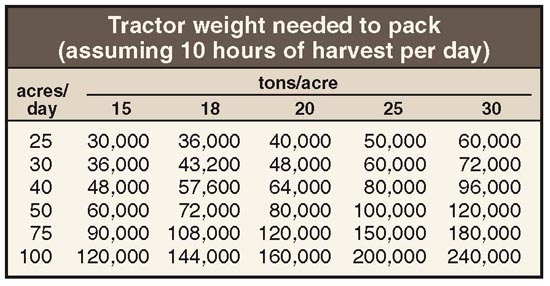

It's difficult to appreciate the phenomenal volume brought into corn silage bunkers with custom harvesters or well-equipped larger dairies. One dairy I worked with boasted about adding a sixth truck to deliver corn silage even more "efficiently" to the bunk. When we did the math, this dairy needed nearly a quarter million pounds of tractor weight to pack effectively. As a reminder, the calculation for tractor packing weight is 800 times the tons per hour delivered to the bunker. The table shows some example packing weight needs.

The need to keep the custom harvester moving is understandable; after all, time is money. But when you've invested tens (or hundreds) of thousands of dollars in the crop at the point of harvest, maybe it's time to consider paying a premium to the harvesting crew to slow down. Assuming $400 per hour to harvest and deliver corn silage to the bunker and 10,000 tons silage harvested, a dairy could afford to pay for an additional 15 hours of harvesting time if it resulted in a 1 percent improvement in dry matter recovery (or reduction in shrink) via better packing.

Oxygen is the enemy . . .

The benefit of efficient and effective packing is the exclusion of oxygen. At harvest, the quicker oxygen is excluded (thus, reducing yeast activity), the more efficient the front-end fermentation can be (providing better dry matter recovery). At feedout, the more densely packed the forage and the less oxygen infiltration at the face, the less secondary fermentation (shrink) can occur.

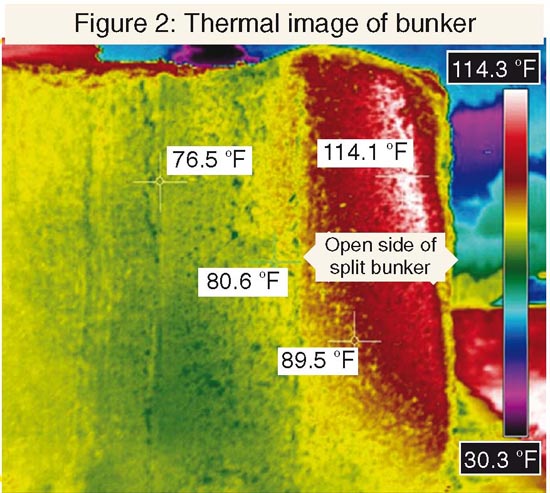

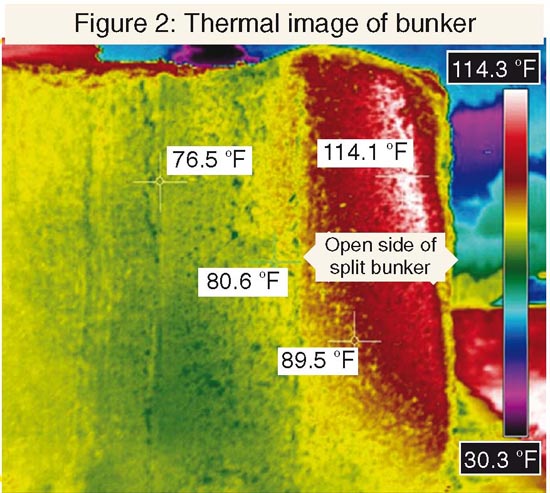

The simplest way to demonstrate the impact of oxygen: Think of the depth of the slime layer of an uncovered bunker six months after storage (usually 6 to 12 inches). Compare that to a well- packed, plastic-covered bunker (2 to 4 inches). Next, compare that to a bunker with a layer of oxygen-barrier plastic (near zero). Figure 1 is another visual example. This is a thermal image of a well-managed split bunker. The producer even hand-sprayed acid on the sidewall to reduce spoilage. Yet, it is clear that weeks of oxygen penetration (secondary fermentation) has deteriorated the quality of several inches of silage.

The value of going from a good manager (15 percent storage plus feedout shrink) to a great manager (10 percent shrink) is at least $3,000 per 100 cows per year (assumes 1,000 tons corn silage annually per 100 cows). Much of that improvement centers around reduced exposure to oxygen. For those questioning the math (5 percent times $35 per ton value corn silage), remember that the shrink that is occurring is highly digestible nutrients - the bugs consume sugars, not fiber. Therefore, the cost of replacing that dry matter is essentially the cost of corn grain, not corn silage. If you are using most of the good management practices listed below but only have average density, you are leaving money on the table.

If you know or suspect you have room for improvement in bunker density, here's an action plan:

A dozen years ago I was involved with a field study in eastern Wisconsin with a local feed supplier and extension dairy specialist. Nearly 200 samples of corn and hay silage from a range of storage structures were taken and analyzed for fermentation profiles. Among the findings of that study: a minority of bunker silo samples met the density guidelines of 15 pounds per cubic foot (PCF) on a dry matter basis.

Fast forward to the last eight months - have we made much progress? Based on my bunker density measurements on several dozen farms in Wisconsin, unfortunately, not so much. Only a handful of corn silage bunkers exceeded the 15 PCF threshold; a slightly higher percentage of hay silage bunkers met that target.

How can this happen? The density targets are not new, and strategies for effective bunker silo filling are well-known. Most of these dairies were very well managed, and many of the owners/managers were surprised with the lower-than-expected density results, commenting they had more or bigger tractors packing than they "used to." It is my opinion that the two most common failures are tractor packing weight and packing depth of silage layers.

The 800 rule . . .

It's difficult to appreciate the phenomenal volume brought into corn silage bunkers with custom harvesters or well-equipped larger dairies. One dairy I worked with boasted about adding a sixth truck to deliver corn silage even more "efficiently" to the bunk. When we did the math, this dairy needed nearly a quarter million pounds of tractor weight to pack effectively. As a reminder, the calculation for tractor packing weight is 800 times the tons per hour delivered to the bunker. The table shows some example packing weight needs.

The need to keep the custom harvester moving is understandable; after all, time is money. But when you've invested tens (or hundreds) of thousands of dollars in the crop at the point of harvest, maybe it's time to consider paying a premium to the harvesting crew to slow down. Assuming $400 per hour to harvest and deliver corn silage to the bunker and 10,000 tons silage harvested, a dairy could afford to pay for an additional 15 hours of harvesting time if it resulted in a 1 percent improvement in dry matter recovery (or reduction in shrink) via better packing.

Oxygen is the enemy . . .

The benefit of efficient and effective packing is the exclusion of oxygen. At harvest, the quicker oxygen is excluded (thus, reducing yeast activity), the more efficient the front-end fermentation can be (providing better dry matter recovery). At feedout, the more densely packed the forage and the less oxygen infiltration at the face, the less secondary fermentation (shrink) can occur.

The simplest way to demonstrate the impact of oxygen: Think of the depth of the slime layer of an uncovered bunker six months after storage (usually 6 to 12 inches). Compare that to a well- packed, plastic-covered bunker (2 to 4 inches). Next, compare that to a bunker with a layer of oxygen-barrier plastic (near zero). Figure 1 is another visual example. This is a thermal image of a well-managed split bunker. The producer even hand-sprayed acid on the sidewall to reduce spoilage. Yet, it is clear that weeks of oxygen penetration (secondary fermentation) has deteriorated the quality of several inches of silage.

The value of going from a good manager (15 percent storage plus feedout shrink) to a great manager (10 percent shrink) is at least $3,000 per 100 cows per year (assumes 1,000 tons corn silage annually per 100 cows). Much of that improvement centers around reduced exposure to oxygen. For those questioning the math (5 percent times $35 per ton value corn silage), remember that the shrink that is occurring is highly digestible nutrients - the bugs consume sugars, not fiber. Therefore, the cost of replacing that dry matter is essentially the cost of corn grain, not corn silage. If you are using most of the good management practices listed below but only have average density, you are leaving money on the table.

If you know or suspect you have room for improvement in bunker density, here's an action plan:

- Make sure layers being packed are 6 inches or less: thicker layers trap more oxygen, and the actual pounds of effective packing weight is greatly reduced.

- Calculate the packing tractor weight needed versus actual packing weight. If the weight comes up short (in approximate order of ease), Add weight to the front or back of tractors.

- Add weights to the wheels or tires (fluid).

- Get more or bigger tractors.

- Slow down harvest.

If the last three options are not feasible (not enough room to safely add a tractor, for example), then consider adding another blade tractor, and fill two bunkers simultaneously.

A word about hay silage . . .

Given that hay silage is usually considered more difficult to pack, why are more hay silage bunkers meeting density targets? (Remember, though, a majority still could be improved.) Again, it comes back to tons per hour delivered to the bunker. Even if you harvest twice as many acres per hour with hay silage, the tons per hour for first crop would likely be about 50 percent of the corn silage and even lower for subsequent cuttings. This gives the packing tractors a chance of keeping up. Take a moment to do the 800 rule calculation for your first crop and get an estimate for your corn silage, as well.

In addition to the standard bunker silo management tips (cover with plastic, use tires, treat with a quality, crop-specific inoculant), the last 10 years have seen a number of shrink-reducing bunker management improvements including:

Click here to return to the Crops & Forages E-Sources

090510_327

A word about hay silage . . .

Given that hay silage is usually considered more difficult to pack, why are more hay silage bunkers meeting density targets? (Remember, though, a majority still could be improved.) Again, it comes back to tons per hour delivered to the bunker. Even if you harvest twice as many acres per hour with hay silage, the tons per hour for first crop would likely be about 50 percent of the corn silage and even lower for subsequent cuttings. This gives the packing tractors a chance of keeping up. Take a moment to do the 800 rule calculation for your first crop and get an estimate for your corn silage, as well.

In addition to the standard bunker silo management tips (cover with plastic, use tires, treat with a quality, crop-specific inoculant), the last 10 years have seen a number of shrink-reducing bunker management improvements including:

- Oxygen barrier plastic layer

- Sidewall and overlapping plastic strategies

- Aerobic stability technology inoculants that drastically decrease secondary heating at feedout

- Facing equipment to reduce oxygen penetration at feedout

- Other effective weighting options besides tires to minimize air infiltration under the plastic

- Care to avoid excessive packing on top that can lead to spoilage (rupturing cell walls)

090510_327